H acid is a very important naphthalene dye intermediate. It is widely used in the production of acidic and reactive dyes, and can also be used in the pharmaceutical industry. In the acid precipitation process, sulfuric acid or hydrochloric acid is added to precipitate H acid monosodium salt. The waste mother liquor obtained after filtration is H acid production wastewater with high concentration, high acidity, high salinity and high color. If not treated, it will inevitably cause environmental pollution.

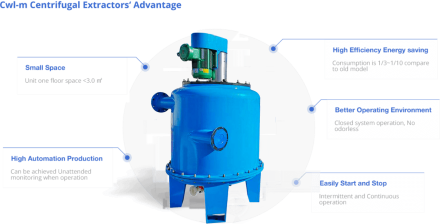

After long-term experiments, it is more appropriate to use extraction method in the treatment process of H acid wastewater. The extraction method is a method suitable for treating wastewater with high biological toxicity, high organic matter concentration, and CODCr that is difficult to biodegrade. The centrifugal extraction equipment produced by Zhengzhou TIEI Extraction selects suitable extraction agents and uses complex extraction to achieve good treatment results.

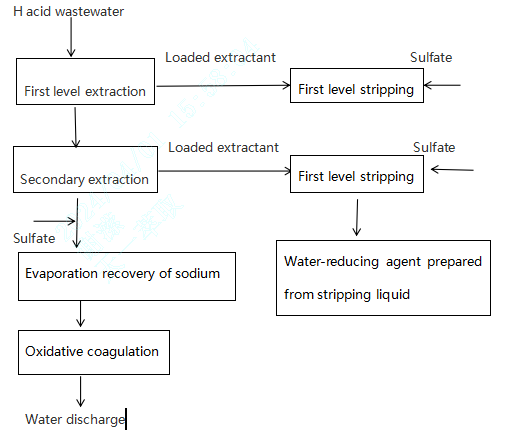

H acid wastewater treatment process:

- Exctraction section

In the process of H acid wastewater treatment, complex extraction method is used, and a two-stage cross-flow extraction process is used for treatment. After adjusting the pH of H-acid wastewater, the extraction agent and waste mother liquor are injected into the centrifugal extractor in a certain proportion, and the mixture and mass transfer are carried out inside the body, and the naphthalene sulfonic acid organic matter in the wastewater is separated under the action of centrifugal force.

2. Stripping section

The stripping section uses one-stage cross-flow stripping to separate the high-concentration stripping liquid, and then concentrate the stripping liquid in subsequent sections to produce naphthalene-based water-reducing agent.