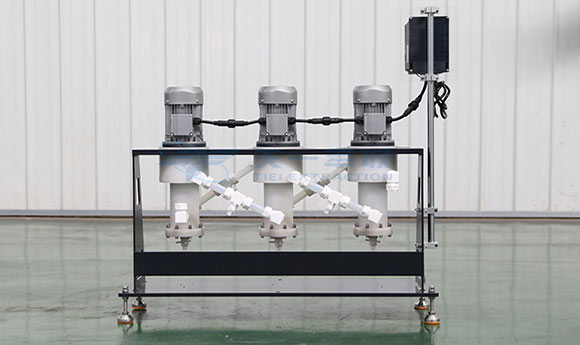

In laboratory extraction processes, choosing a reliable centrifugal extractor with stable performance and high separation efficiency is essential. As one of the core products of Zhengzhou Tiei Extraction Technology Co., Ltd., the CWL-M Series Laboratory Centrifugal Extractor has, since its launch, played a vital role in laboratory research and pilot-scale applications across fine chemicals, pharmaceuticals, environmental protection, and other fields. The series mainly includes two models—CWL25-M and CWL50-M—designed to meet different throughput requirements in liquid–liquid extraction processes.

The working principle of the CWL-M Laboratory Centrifugal Extractor is based on a combined structure of a high-speed rotating drum and a turbine disc. Driven by a motor, the impeller rotates at high speed, allowing the light and heavy liquid phases to achieve thorough mixing and mass transfer within an extremely short time. Subsequently, under the action of strong centrifugal force, the two phases are rapidly separated and discharged through their respective outlets, enabling continuous and highly efficient extraction. This mechanism not only improves extraction efficiency but also significantly reduces solvent consumption and processing time.

When selecting liquid–liquid extraction equipment, users should look beyond the basic specifications and evaluate their actual experimental requirements. To ensure complete compatibility between equipment and process, the following four key factors must be considered:

- Choose the right model based on throughput requirements.

Different laboratory or pilot-scale processes have clear demands on processing capacity. Within the CWL-M series, the CWL25-M and CWL50-M models correspond to different flow ranges. Users should select the model that matches their routine sample volume to avoid underutilization or overload. - Match impeller type to material characteristics.

For material systems prone to emulsification, a gentler inner-impeller structure is recommended to prevent excessive emulsification and ensure a smooth, controllable mass transfer process. Zhengzhou Tiei Extraction provides professional impeller selection guidance tailored to users’ material systems. - Ensure component materials are compatible with the chemical environment.

The centrifugal extractor’s components must offer excellent resistance to corrosion and solvents. For example, elbows in small-scale units are often made of polypropylene (PP), while interconnection parts commonly use polytetrafluoroethylene (PTFE). In medium and large-scale equipment, composite materials or reinforced hoses are applied in pressure-demanding conditions to guarantee long-term stable operation. - Pay attention to the connection between the drum and motor shaft.

CWL-M laboratory-scale centrifugal extractor typically adopt a bolt connection structure. This design is simple to assemble and disassemble, offers higher reliability, and is less prone to damage compared with traditional key connections—making it especially suitable for laboratory environments that require frequent adjustment and cleaning.

In conclusion, selecting a suitable laboratory centrifugal extractor requires a systematic evaluation of multiple factors, including model, structure, and material compatibility. As a leading supplier of liquid–liquid extraction equipment, Zhengzhou Tiei Extraction Technology Co., Ltd. not only offers the CWL-M Series Centrifugal Extractor but also provides end-to-end professional services—from process consultation and equipment selection to after-sales support. For more detailed information or customized solutions, please feel free to contact our team of technical engineers.

Email: sales@tieiextraction.com

Whatsapp: +86 19069612820