- About Us

- Equipment

- Solution

- Cases

- News

- Service

- Contact us

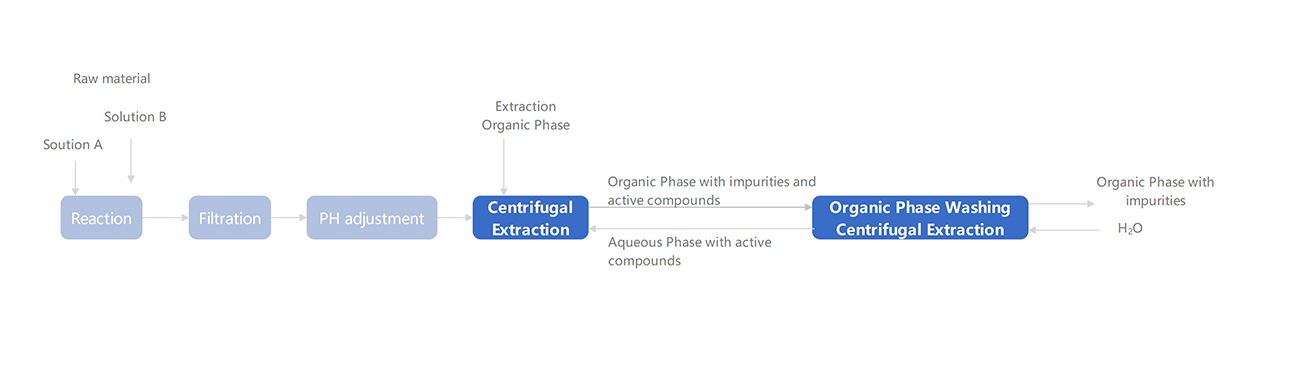

The extraction process for active pharmaceutical ingredients (API) in the pharmaceutical industry involves the centrifugal extractor solvent extraction method for reactive extraction of intermediates and washing operations. The extraction process is part of a larger process that includes fermentation, intermediate reaction, washing, and purification.

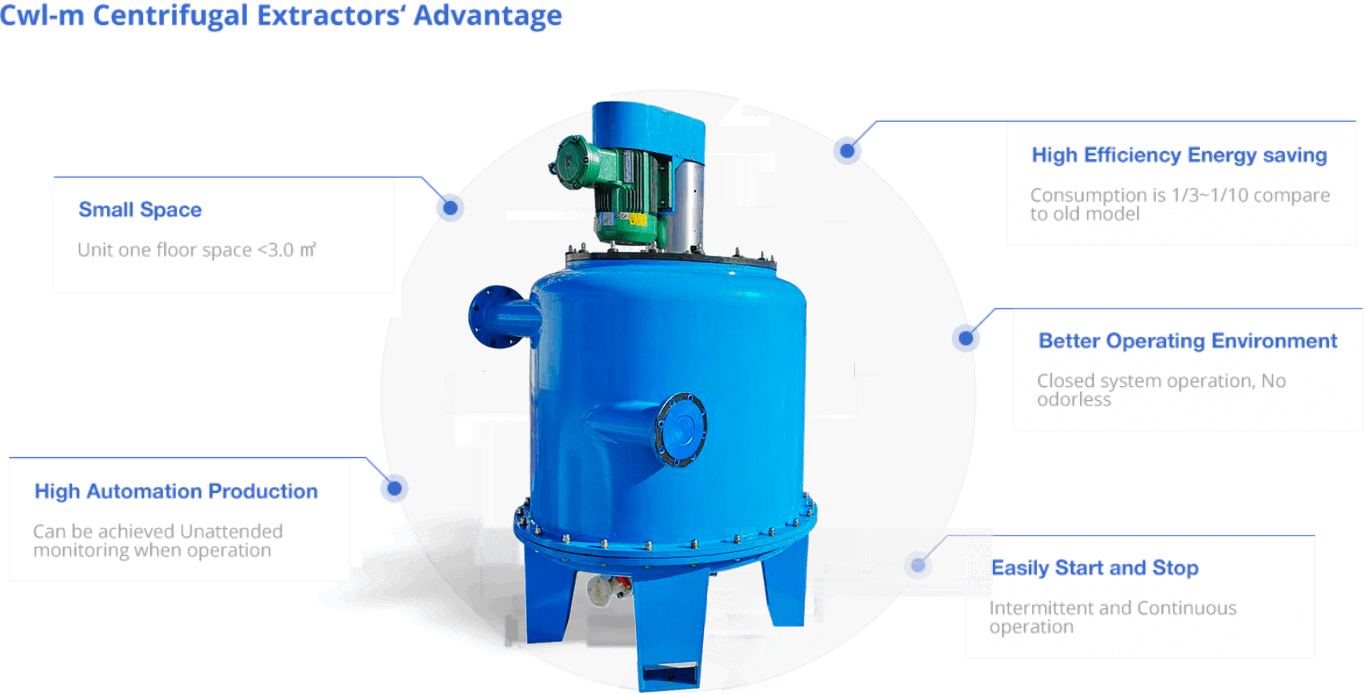

Centrifugal extractors are widely used in the pharmaceutical industry for the extraction and separation of API. The synthesis and extraction of API are performed using centrifugal extractors, which have short retention time between stages, rapid phase separation, high extraction efficiency, and save investment costs and solvent recovery and regeneration costs.

Step

Pretreatment: First, pretreat the API reaction solution to remove solid impurities and unreacted raw materials. This can be achieved by filtration or centrifugation.

Extraction: Then, select an appropriate extraction agent to extract the desired API from the reaction solution. The extraction agent should be immiscible with the reaction solution, but be able to form a stable complex or emulsion with the API in the reaction solution. Commonly used extraction agents include organic solvents, supercritical fluids, etc.

Separation: Evaporate or centrifuge the extracted solvent to obtain pure API products. In this step, further processing may be required to obtain high-purity API, such as crystallization, distillation, etc.

Washing: In order to remove residual solvents and other impurities in the API, water washing can be performed. This can be achieved by suspending the API in water and then separating out the water and residual solvent.

Drying: Finally, the API is dried to remove any remaining moisture and other impurities and bring it to the required purity and quality standards.

It should be noted that the specific extraction and separation steps may vary depending on the type of API, reaction conditions, and required purity. Therefore, when extracting and separating API reaction solutions, it is necessary to carefully consider various factors and select the most suitable method to achieve the goal.

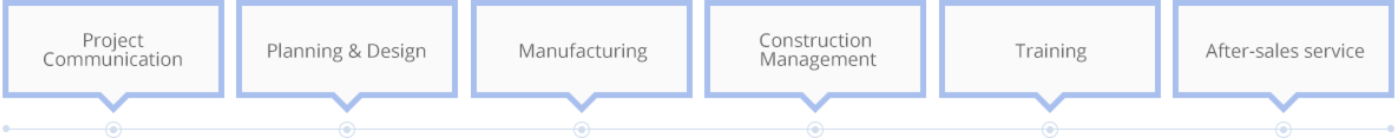

Supporting One-stop service:

Project communication, planning, scheme design, equipment manufacturing, process operating, and construction management, training and project after-sales service.

Tiei extraction recommend LABORATORY EXTRACTION EQUIPMENT, to help you understand the extraction equipment, to verify technolgoy process and equipment characteristics.

Also you can view relevant CUSTOMER CASES, EXTRACTION EQUIPMENT SOLUTIONS and RESEARCH TRENDS and browse all extraction equipment.

Leave your questions and we will get in touch with you as soon as possible

Leave your questions and we will get in touch with you as soon as possible