- About Us

- Equipment

- Solution

- Cases

- News

- Service

- Contact us

Lithium ore is currently the main source of lithium raw materials in China. Solid lithium ores such as spodumene and lepidolite are used to produce lithium carbonate and other lithium products.

The method of extracting lithium from lithium-containing brine is mainly to evaporate and concentrate, separate and remove impurities, and deeply remove calcium and magnesium ions to obtain a high-purity lithium-containing solution, and then precipitate the lithium-containing solution to obtain lithium products.

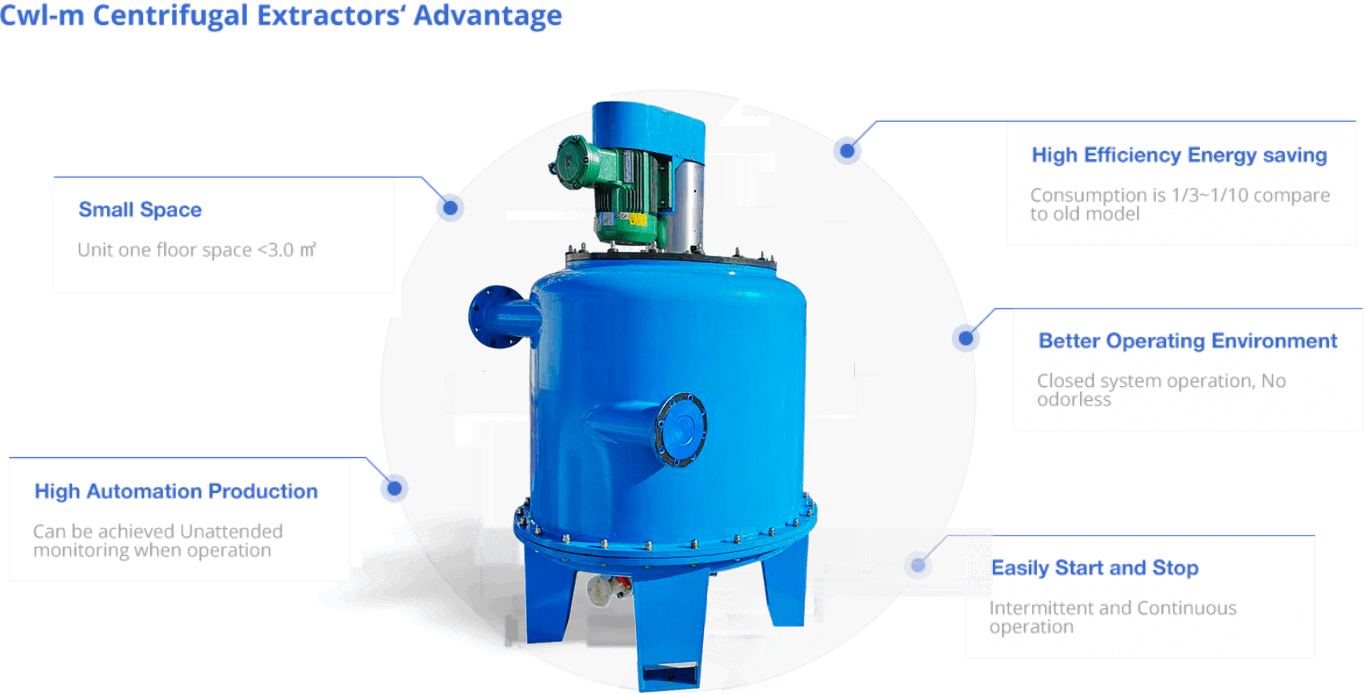

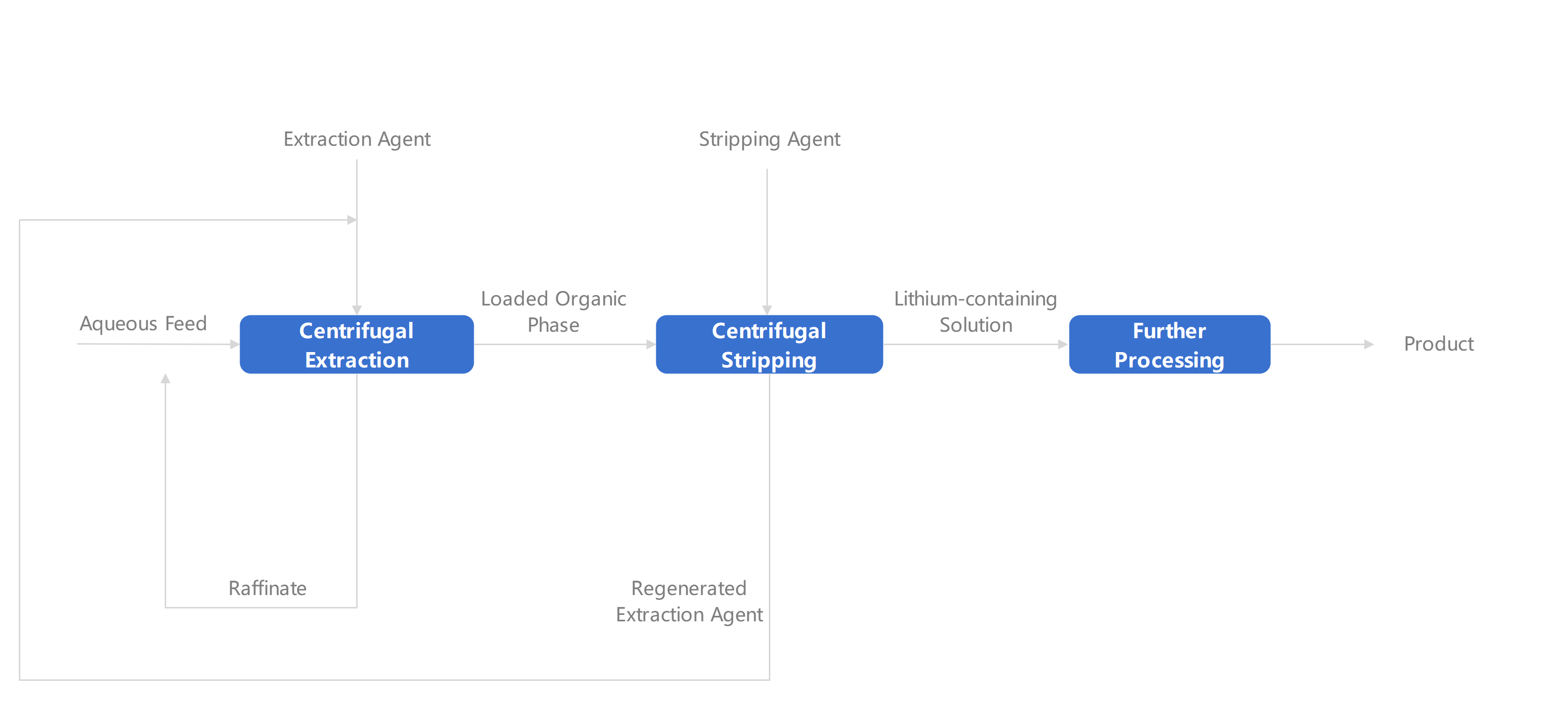

Zhengzhou Tiei Extraction has launched a method of centrifugal extraction - stripping separation - purification for extracting lithium. This method uses the CWL-M series centrifugal extractor as the core extraction equipment to extract the lithium-containing solution under high pH conditions, achieving efficient extraction of lithium and separation from a large number of impurity elements such as Na, K and B. Then, stripping is carried out through a multi-stage continuous countercurrent process to achieve efficient recovery of lithium. The process has a large processing capacity, solvent recycling, and a high total lithium yield. At the same time, the process flow is short, the equipment is simple, the investment is small, and it is easy to apply industrially.

1.Using an extraction system containing the composite extraction agent, the lithium-containing solution is extracted and separated after pH adjustment to obtain a lithium-loaded organic phase.

2.The obtained lithium-loaded organic phase is stripped to obtain a lithium-loaded stripping solution.

3.The obtained stripping solution is heat-treated and separated to obtain a lithium product and a mother liquor after separation.

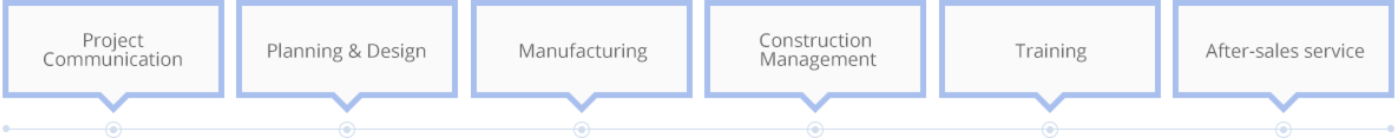

Supporting One-stop service:

Project communication, planning, scheme design, equipment manufacturing ,process operating, and construction management, training and project after-sales service.

Tiei extraction recommend LABORATORY EXTRACTION EQUIPMENT, to help you understand the extraction equipment, to verify technolgoy process and equipment characteristics.

Also you can view relevant CUSTOMER CASES, EXTRACTION EQUIPMENT SOLUTIONS and RESEARCH TRENDS and browse all extraction equipment.

Leave your questions and we will get in touch with you as soon as possible

Leave your questions and we will get in touch with you as soon as possible