- About Us

- Equipment

- Solution

- Cases

- News

- Service

- Contact us

The production of antibiotic is the earliest and most important application of our liquid liquid centrifugal extractor. Tiei Extraction® centrifuges are widely used for extracting or purifying the antibiotics from fermentation broth. We can effectively separate solutions containing antibiotics by centrifugal force generated by centrifuges, providing a foundation for further purification.

Antibiotics :

Extractants:

The extraction process of antibiotic can be : 1. multi-stage countercurrent extraction; 2. multi-stage cross flow extraction . In multi-stage countercurrent extraction, the feed liquid is added to the first stage and gradually moves downwards, while the extractant is added to the last stage and gradually moves forward. The direction of feed liquid movement is opposite to the direction of extractant movement, so it is called countercurrent extraction . In cross flow extraction, only the extractant is added in the last stage, so compared to cross flow extraction, the consumption of extractant is lower, resulting in a higher average concentration of the extract solution.

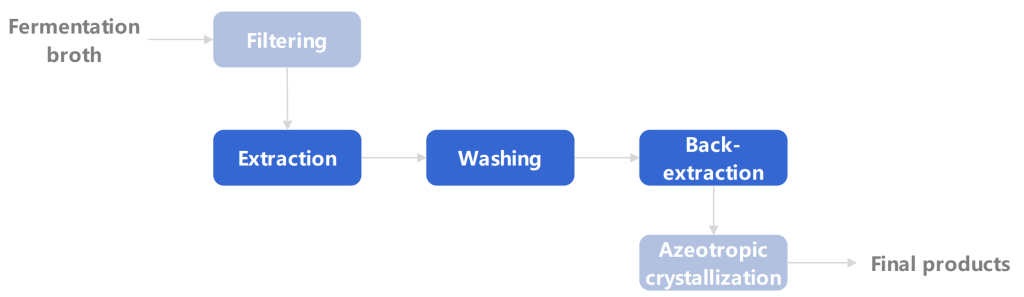

The steps for extracting penicillin from fermentation broth by multi-stage countercurrent extraction with our three- stages cascade of centrifuges:

Step 1- Extraction: Use H2SO4 to adjust the PH of the filtered fermentation broth, add butyl acetate in a certain proportion and an appropriate amount of demulsifier , then countercurrent extraction at low temperature (like 5 degrees).

Step 2 - Washing : Butyl acetate which containing the penicillin go to the centrifuges for washing out the water soluble pigments and impurities.

Step 3 - Back extraction : use NaHCO3 as back extration agent, add 1.5% NaHCO3 solution in the loaded Butyl acetate to extract the target products back.

Precautions for using a centrifuge to extract penicillin:

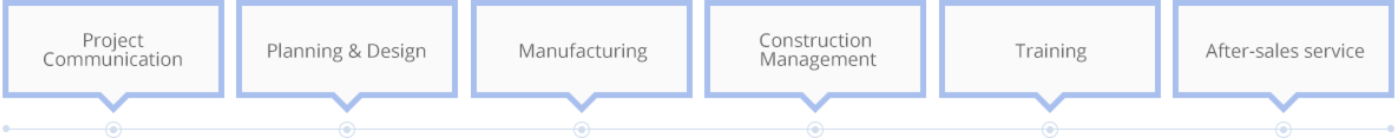

Supporting One-stop service:

Project communication, planning, scheme design, equipment manufacturing ,process operating, and construction management, training and project after-sales service.

Tiei extraction recommend LABORATORY EXTRACTION EQUIPMENT, to help you understand the extraction equipment, to verify technolgoy process and equipment characteristics.

Also you can view relevant CUSTOMER CASES, EXTRACTION EQUIPMENT SOLUTIONS and RESEARCH TRENDS and browse all extraction equipment.

Leave your questions and we will get in touch with you as soon as possible

Leave your questions and we will get in touch with you as soon as possible