Lithium extraction from brine (concentrated brine, natural brine)

Lithium is a highly reactive alkali metal. Because of its excellent thermal and electrical conductivity, it is an ideal choice for a variety of uses such as power batteries (EV batteries) and energy storage. With the increasing demand for lithium, the development of lithium extraction technology from salar brine has become increasingly important. At present, common methods for lithium extraction from salar brine include precipitation, solvent extraction, and adsorption. Among them, solvent extraction has become a green, efficient, and low cost lithium extraction from brine process.

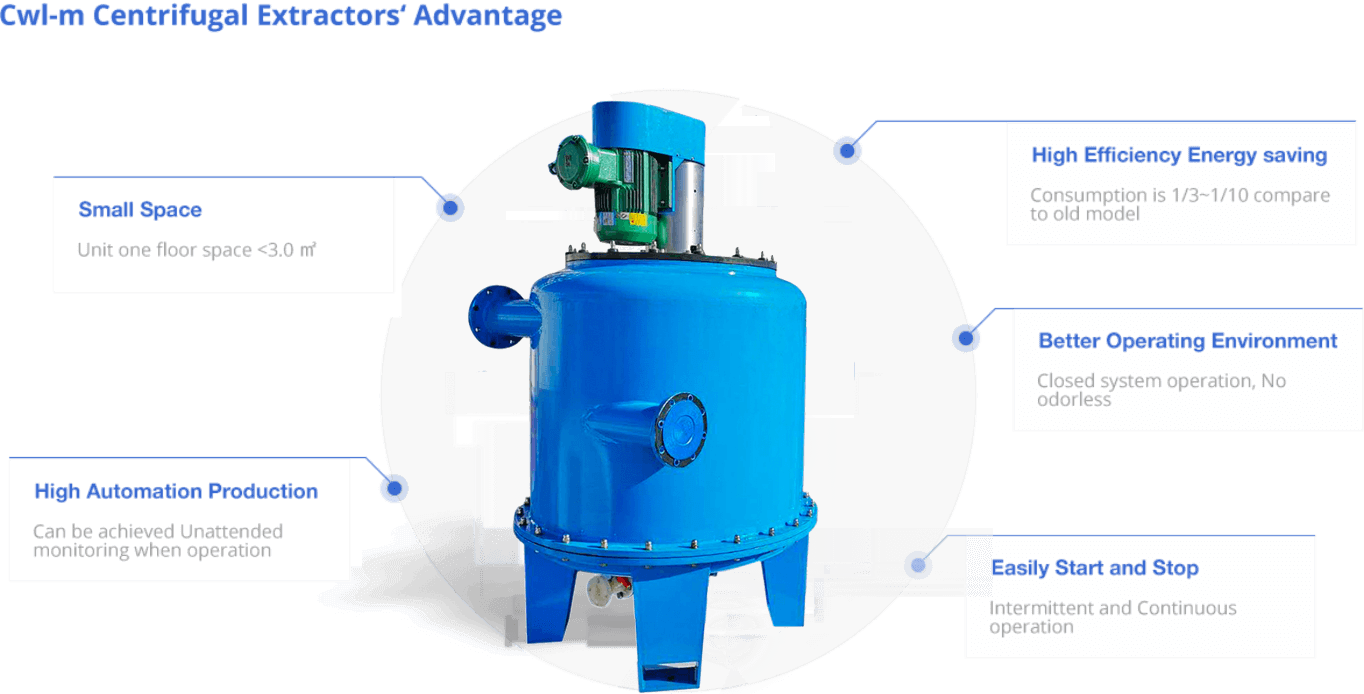

In view of the particularity of lithium extraction from salar brine, Zhengzhou Tiei Extraction Company has launched the CWL-M series centrifugal extractors with independent intellectual property rights. The equipment is made of all-fluorine materials and is highly resistant to corrosion, solving the problems of severe equipment corrosion and large dissolution loss of extraction agent in the process of lithium extraction from salar brine. At the same time, under the same processing volume, the power consumption of this series of centrifugal extractor is only 10% to 30% of that of traditional annular gap models. It also has short residence time, rapid phase separation, high extraction efficiency, and saves investment costs and solvent recovery and regeneration costs. It is worth mentioning that Zhengzhou Tiei Extraction has improved and upgraded the equipment for the process of lithium extraction from salar brine, effectively ensuring the stable operation of the construction unit's high capacity industrial production line and achieving full production and meets standards.

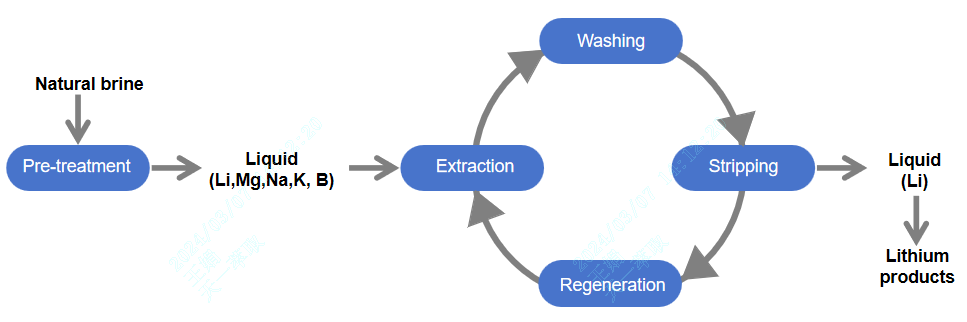

Lithium extraction from natural brine: It mainly includes three steps: brine mining, lithium extraction and purification. It has high lithium extraction efficiency and can effectively develop salt lakes.

Lithium extraction from concentrated brine: The concentrated brine is dried in the salt field, and then magnesium and lithium are separated in the workshop, and lithium is extracted after concentration.

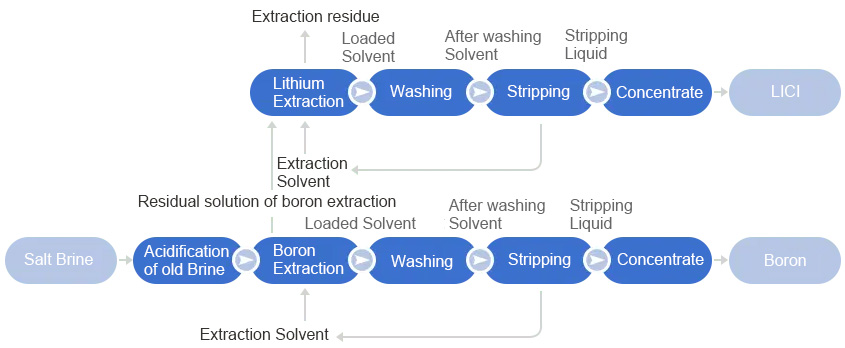

Extraction ingredients: Brine extracts lithium, boron, magnesium, iodine, bromine and other elements

Lithium extraction fromsalar brine process:

1.Select the appropriate extraction agent according to the liquid system, select the CWL650-M centrifugal extractor as the equipment, select the number of stages according to the processing volume and efficiency, and then perform extraction. Inject the salar brine and the extraction agent into the centrifugal extractor in a certain proportion. With the help of the rotation of the drum, the two phases are quickly mixed and dispersed through the impeller to complete the mixed mass transfer process. The mixed liquid enters the drum under the action of the vortex disk. Under the action of centrifugal force, the two phases liquid are separated quickly and discharged from the machine through different outlets to complete the two phase separation process.

2.The organic phase after extraction is added with the stripping agent and re-injected into the centrifugal extractor for stripping, the extraction agent is separated from the organic phase, the extraction agent is recycled, and the organic phase after stripping is processed in subsequent sections to obtain the finished lithium carbonate product.

Note: The focus of the process is on the selection of the extraction agent and the selection of the extraction equipment. Efficient extraction equipment can effectively extract lithium elements, and the extraction rate is very high, which meets the industrial production needs of customers.

Supporting One-stop service:

Project communication, planning, scheme design, equipment manufacturing ,process operating, and construction management, training and project after-sales service.

Tiei extraction recommend LABORATORY EXTRACTION EQUIPMENT, to help you understand the extraction equipment, to verify technolgoy process and equipment characteristics.

Also you can view relevant CUSTOMER CASES, EXTRACTION EQUIPMENT SOLUTIONS and RESEARCH TRENDS and browse all extraction equipment.

Leave your questions and we will get in touch with you as soon as possible

Leave your questions and we will get in touch with you as soon as possible