- About Us

- Equipment

- Solution

- Cases

- News

- Service

- Contact us

It mainly used for laboratory-level small-scale experiments. It has a compact structure and simple and convenient operation. It can directly simulate multi-stage countercurrent extraction and multi-stage cross-flow using a small amount of material liquid.

Centrifugal extractor is a new, fast and efficient liquid-liquid extraction and separation equipment. It is fundamentally different in working principle from traditional extraction equipment such as mixer settlers and extraction towers. The centrifugal extractor uses the motor to drive the drum to rotate at high speed. Two liquids with different densities and immiscible liquids are mixed and mass transferred under the action of shear force generated by the rotation of the drum or blades, and are rapidly separated under the action of centrifugal force generated by the high-speed rotation of the drum.

Whatsapp: +8619069612820

Email: sales@tieiextraction.com

Organic Acid Fermentation

Organic Acid Fermentation Fine Chemical

Fine Chemical Hydrometallurgy

Hydrometallurgy Environmental

Environmental

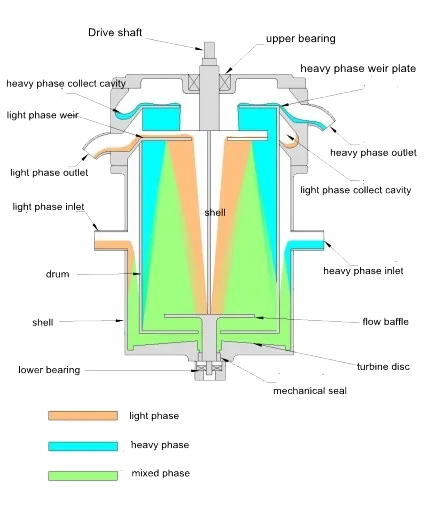

Mixing and Mass transfer process

The light and heavy phase solutions entering into the internal mixing zone of the shell from the two feed inlets respectively, according to a certain ratio, so that let the two phases are rapidly mixed and dispersed, to complete the mixed and mass transfer process.

Separation process

Under the action of the feeder or turbine disc, the mixed liquor enter in bowl, in the cavity zone, it soon rotated with bowl , under the condition of centrifugal force, during the upward flow process, the heavier liquid is away from bowl center and towards to the bowl wall, while the lighter liquid is away from bowl wall and towards to the center, clarified liquids enter in collecting chamber through their respective weirs and discharged from light and heavy phase outlets, to complete the separation process.

1. Simply and stable structure

Top-suspension structure, no bearing and mechanical seal at the bottom of equipment, no leakage risk, easy for maintenance and save maintenance cost, long service life.

2. Energy- Saving

Large capacity, more energy -saving (comparing if under same capacity condition, the power consumption is 1/10-1/3 to traditional annular type extractor)

3.Corrosion resistance

Machine produced by perfluoro polymer material, resistant with corrosion of strong acid (Hydrochloric acid, mixed acid etc.)

4.Good effects of mixing and separation

Various hybrid structures could be chosen, good separation effect, adapt to easily emulsified system.

5.Easy to change heavy phase weir

When changing liquid system, heavy phase weir could be quickly replaced, simple and easy operation.

6.Low liquid residual

Machine with small valid volume

7.Highly automated program

Realize timely monitoring on-line, optional on-line cleaning system of GMP standard, completely adapt to intermittent and continuous running.

| Model | Diameter of Bowl (mm) | Applicable rotating speed | Max. Mixing Flux(L/H) | Pipe diameter of inlet and outlet(mm) | Two-phase flow ratio range | Motor Power(KW) | Unit Dimension |

| CWL25-M | 25 | 5000-7000 | ≤10 | DN10 | 1/30~30/1 | 0.09 | 230×230×800 |

| CWL50-M | 50 | 5000-7000 | ≤50 | DN20 | 1/30~30/1 | 0.18 | 400×370×900 |

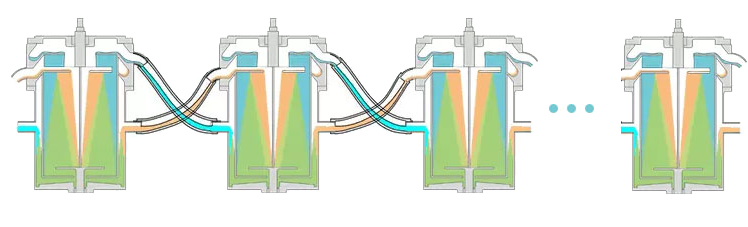

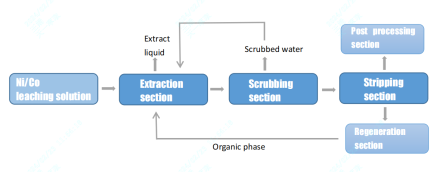

Usually, you would have multiple centrifugal extractors in series for extraction, scrubbing and stripping(and perhaps others). The number of stages needed in each section of the process would depend on the process design requirements(necessary extraction factor).The process design is based on testing data,to get real operating data on a laboratory machine, and be able to use that data is very helpful. You have to vet your process, and know what challenges you're gonna have in your design, and what conditions to expect. So the pilot plant is absolutely the first step.

Tiei extraction recommend LABORATORY EXTRACTION EQUIPMENT, to help you understand the extraction equipment, to verify technolgoy process and equipment characteristics.

Also you can view relevant CUSTOMER CASES, EXTRACTION EQUIPMENT SOLUTIONS and RESEARCH TRENDS and browse all extraction equipment.

Leave your questions and we will get in touch with you as soon as possible

Leave your questions and we will get in touch with you as soon as possible