- About Us

- Equipment

- Solution

- Cases

- News

- Service

- Contact us

Pharmaceutical intermediates are a branch of fine chemicals and are the products of organic synthesis reactions. The extraction and separation of pharmaceutical intermediates mainly uses solvent extraction to perform liquid-liquid mixing and separation operation process. This operation process is used to transfer the required substance from one phase to another, thereby achieving the purpose of extraction, separation, purification, and impurity removal.

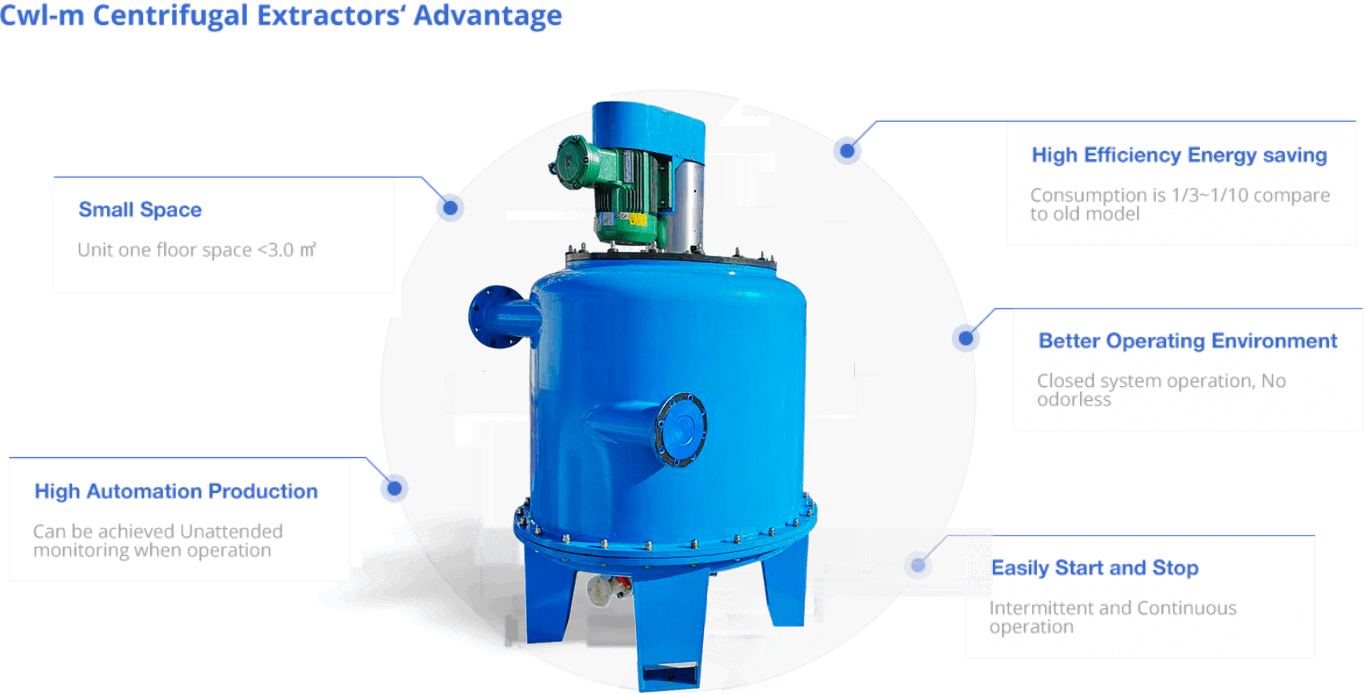

In the process of extracting pharmaceutical intermediates, extraction towers or reactors were mainly used in the past. With the advancement of technology, people's requirements for equipment are getting higher and higher. The extraction effect of traditional equipment can no longer reach the ideal state. In order to better meet the needs of customers, Zhengzhou Tiei Extraction has developed a new type of extraction equipment - centrifugal extractor.

When centrifugal extractors are used to extract and separate pharmaceutical intermediates, they mainly rely on centrifugal force to quickly mix and separate the two-phase liquids. They have fast mixing and mass transfer speed, comprehensive mixing effect, high extraction and separation efficiency, no entrainment, and at the same time, they have a larger processing capacity and are more energy-efficient.

For example, the extraction and separation of furanoxime (2-methoxyimino-2-furanacetic acid).

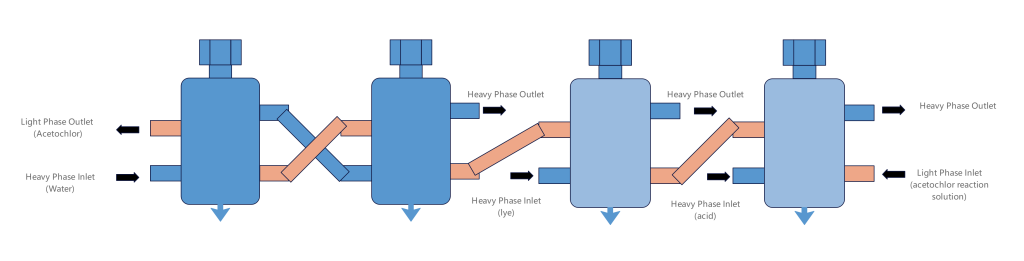

Furanoxime is an important intermediate for the synthesis of cephalosporin antibiotic cefuroxime. The synthesis method is to use acetofuran as the starting material, and then undergo acidic oxidation with sodium nitrite, oxime synthesis with methoxy hydrochloride, and organic solvent extraction and distillation to obtain it. In the preparation process, the suitable extractant is selected, and the CWL-M centrifugal extractor is used for extraction and separation.

First, a certain amount of dichloromethane and a synthetic liquid with a pre-adjusted pH value are injected into the centrifugal extractor through different inlets. In the mixing zone, the feed liquid is rapidly mixed and dispersed through the turbine disc and impeller with the help of the rotation of the drum, and the two-phase solution is fully mass-transferred to complete the mixing and mass-transfer process. The mixed feed liquid enters the drum under the action of the vortex disk. Under the action of centrifugal force, the two phases are separated. The clarified two-phase liquid finally enters the collection chamber through their respective weir plates and is respectively led out of the machine by the guide pipe to complete the two-phase separation process.

Note: In the extraction process, furanoxime is an organic acid, and the pH value has a great influence on its extraction. At a lower pH value, furanoxime is more likely to be distributed in the organic phase.

Supporting One-stop service:

Project communication, planning, scheme design, equipment manufacturing ,process operating, and construction management, training and project after-sales service.

Tiei extraction recommend LABORATORY EXTRACTION EQUIPMENT, to help you understand the extraction equipment, to verify technolgoy process and equipment characteristics.

Also you can view relevant CUSTOMER CASES, EXTRACTION EQUIPMENT SOLUTIONS and RESEARCH TRENDS and browse all extraction equipment.

Leave your questions and we will get in touch with you as soon as possible

Leave your questions and we will get in touch with you as soon as possible