Salt lake distribution: China( Qinghai,Tibet), oversea(Bolivia , Chile, Argentina)

In China, lithium extraction from old brine, single recovery rate is low(<50%),Difficult to expand production capacity. The extraction of lithium from natural brine is greatly limited by Li concentration and technology.

In oversea: Bolivia , Chile, Argentina are known as the "Lithium Triangle". They account for 50%+ of global salt lake lithium resources. But huge amount of fresh water consumption, Long construction cycle, low quality of final product(Li2CO3 etc) make people upset.

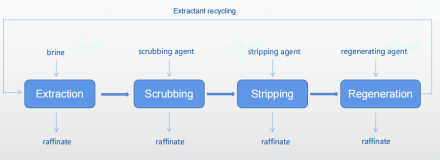

So direct lithium extraction (DLE) technology is expected to break the technical bottleneck of lithium resource utilization in salar/salt lakes. Zhengzhou Tiei Extraction Extraction has launched a centrifugal extraction process equipment that combines the advanced equipment of the CWL-M series new centrifugal extraction machine with the DLE technology to solve the problem. At the same time, lithium extraction rate can be more than 98%.