Driven by the wave of new energy development, lithium cobalt oxide (LiCoO₂) batteries remain the core power source for portable electronic devices such as smartphones and laptops due to their high energy density and stable output performance. As the replacement cycle of electronic products accelerates, the number of spent lithium cobalt oxide batteries worldwide is accumulating at an unprecedented rate. Improper disposal of these waste batteries not only poses potential environmental risks but also leads to a tremendous waste of scarce strategic resources such as cobalt and lithium. Owing to its low energy consumption, high metal recovery efficiency, and environmental friendliness, hydrometallurgical technology has become the mainstream process for recycling spent lithium cobalt oxide batteries.

Hydrometallurgical technology enables the efficient separation and recovery of valuable metals from batteries through processes such as acid leaching, solvent extraction, and precipitation, thereby realizing the circular utilization of resources. The core advantages of this technology include:

High metal recovery rate (cobalt recovery can exceed 98%)

High product purity, allowing direct reuse in new battery production

Low energy consumption and minimal environmental pollution

Mature and scalable process, suitable for industrial application

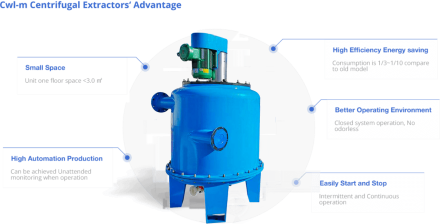

Tiei Extraction CWL-M Series Centrifugal Extractor

Zhengzhou Tiei Extraction Co., Ltd. has been deeply engaged in the field of liquid–liquid separation for many years. Its independently developed CWL-M series centrifugal extractor provides an ideal solution for the solvent extraction process in lithium cobalt oxide battery recycling.

- High mass transfer efficiency, improved recovery rate

The CWL-M centrifugal extractor generates strong centrifugal force through high-speed rotation, allowing two immiscible phases to achieve intense dispersion and mixing during counter-current contact. Its mass transfer efficiency far surpasses that of traditional mixer-settlers, significantly improving metal recovery rates. - Low holdup volume, cost savings

The equipment’s low internal holdup minimizes the retention of valuable extractants and materials, significantly reducing operating costs. - Fully enclosed operation, safe and environmentally friendly

The sealed design prevents VOC emissions, improves the working environment, and meets the stringent environmental protection standards of the battery recycling industry. - High automation and easy operation

With continuous counter-current operation and automated control, the CWL-M series greatly reduces manual labor intensity and ensures process stability.

Successful Application Cases

At present, Tiei Extraction’s centrifugal extractor has been successfully applied in cobalt, nickel, and lithium hydrometallurgical projects at numerous well-known battery recycling enterprises both in China and abroad. One large recycling enterprise adopted the CWL550-M centrifugal extractor for the cobalt–lithium separation stage, achieving a cobalt direct recovery rate of 99.2%. The resulting cobalt sulfate met battery-grade standards, and the entire system operated with high stability and automation, earning strong recognition from the client.

Welcome contact us for more details about CWL-M Series Centrifugal Extractor.

Email: sales@tieiextraction.com

Whatsapp: +86 19069612820