- About Us

- Equipment

- Solution

- Cases

- News

- Service

- Contact us

Application Of Ionic Rare Earth Extraction And Enrichment

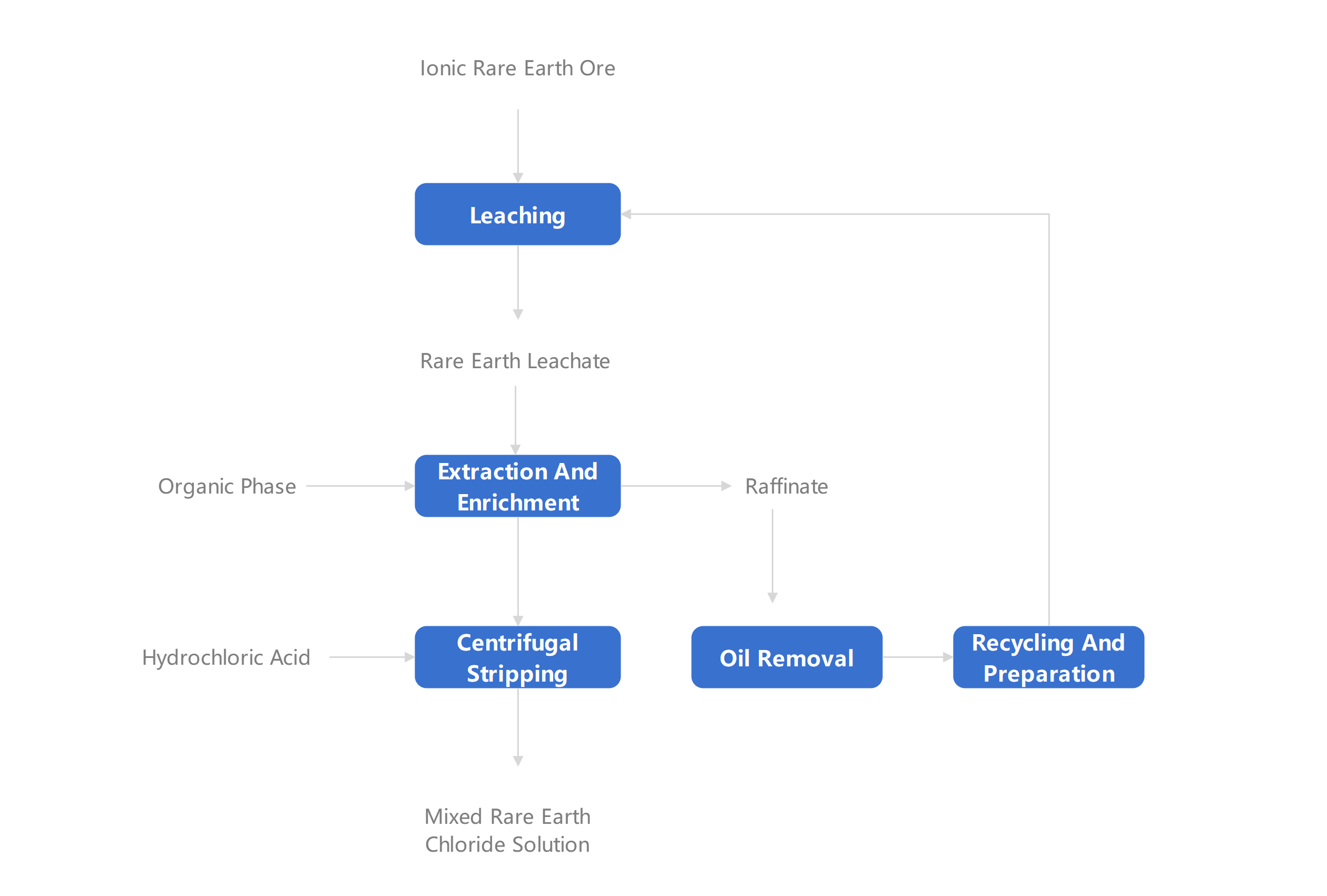

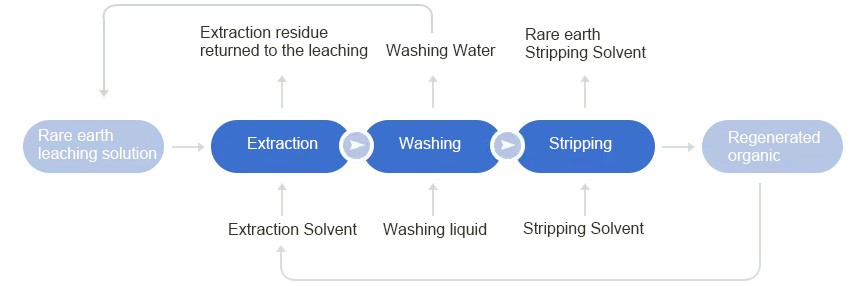

Rare earths are precious strategic resource, our country's medium and heavy rare earth reserves of ionic rare earth mines account for >80% of the world's total, and its output is >95%, which has an absolute competitive advantage. Resource and environmental issues restrict the healthy and sustainable development of ionic rare earth mining enterprises. The precipitation extraction process has the following problems: first, the utilization rate of rare earth resources is low (50%-70%); second, the environmental pollution is serious, and a large amount of ammonia nitrogen wastewater and radioactive waste residues are produced. For the recovery of low-concentration rare earth leachate (only 0.2-2g/L), the extraction method replaces the precipitation method to enrich and recover rare earths, which has great advantages. However, the bottleneck problems that the traditional extraction method has not yet solved are: first, the organic phase is easy to emulsify and the loss is serious; second, conventional extraction equipment cannot achieve high flow ratio and high throughput operation. Therefore, it is urgent to realize high-throughput, high-flow ratio, continuous, stable and efficient extraction enrichment and recovery technology for low-concentration rare earths.

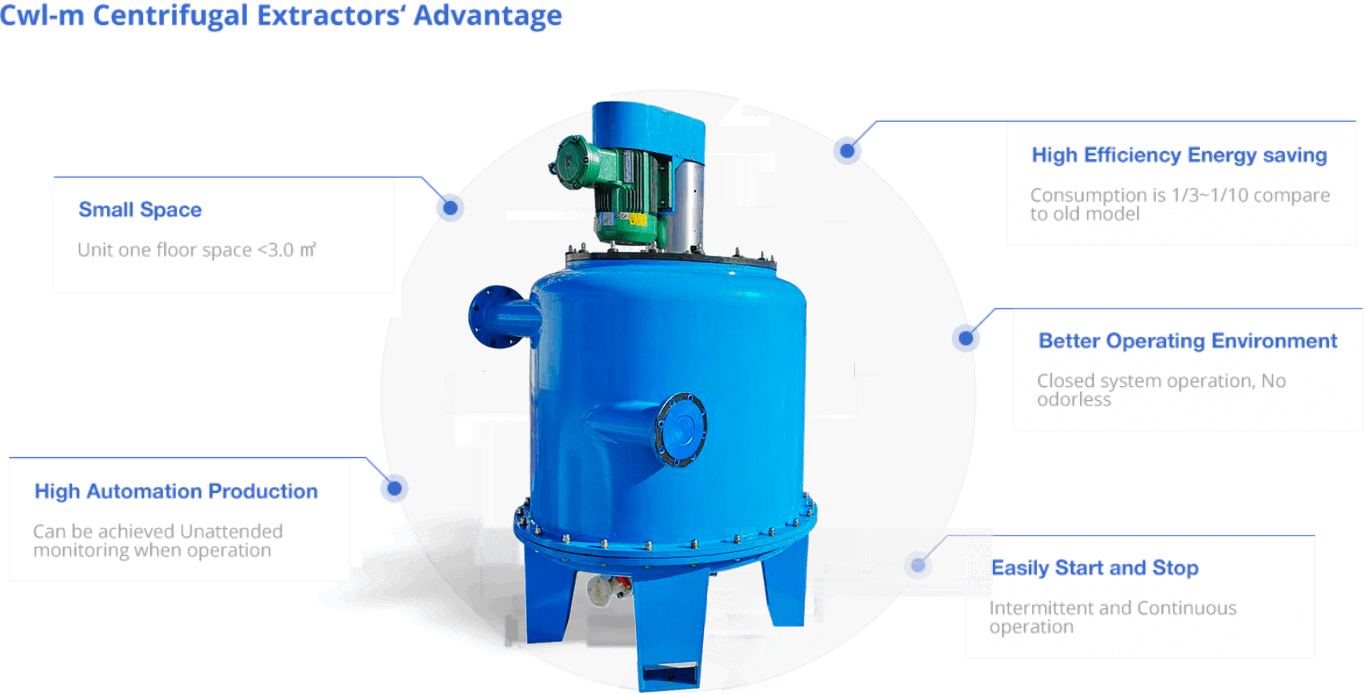

Zhengzhou Tiei Extraction has launched a new type of centrifugal extractor for rare earth metal extraction technology, which perfectly realizes the extraction of industrial rare earth ores with a high flow ratio, and the extraction rate is >98.5%. CWL-M seris liquid-liquid centrifugal extractors not only solves the technical problems of low resource recovery rate and serious pollution of three wastes in the process of leaching, enrichment, separation and purification of ionic rare earth ores, but also greatly reduces the operating cost of equipment and the cost of manpower output, which has effectively promoted the further development of rare earth green development technology.

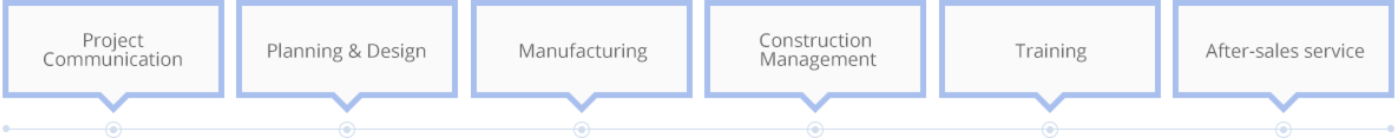

Supporting One-stop service:

Project communication, planning, scheme design, equipment manufacturing ,process operating, and construction management, training and project after-sales service.

Tiei extraction recommend LABORATORY EXTRACTION EQUIPMENT, to help you understand the extraction equipment, to verify technolgoy process and equipment characteristics.

Also you can view relevant CUSTOMER CASES, EXTRACTION EQUIPMENT SOLUTIONS and RESEARCH TRENDS and browse all extraction equipment.

Leave your questions and we will get in touch with you as soon as possible

Leave your questions and we will get in touch with you as soon as possible