More than 90% of Manganese ore (Mn metal) in the world is consumed in the iron and steel industry producing manganese series ferroalloys, and the remaining 10% is consumed in non-ferrous metallurgy, chemical industry, battery, electronics, construction, agriculture and other industries.

With the rapid growth of the demand for lithium batteries for electric vehicles and energy storage, the market demand for manganese sulfate, as one of the important raw materials for producing lithium manganate, will become more urgent.

Battery grade manganese sulfate has extremely strict requirements on the content of various impurities, of which the content of iron, copper, lead, zinc and chromium is less than 10x10-6, and the content of calcium, magnesium, sodium and potassium is less than 50x10-6. However, it is very difficult to remove impurities of calcium, magnesium, potassium and sodium lamp elements in manganese sulfate solution, and it is difficult to obtain high-purity products by chemical precipitation, salting out crystallization, ion exchange or chemical adsorption.

However The solvent extraction method is effective in purifying and separating various metal elements, and reduces environmental pollution.

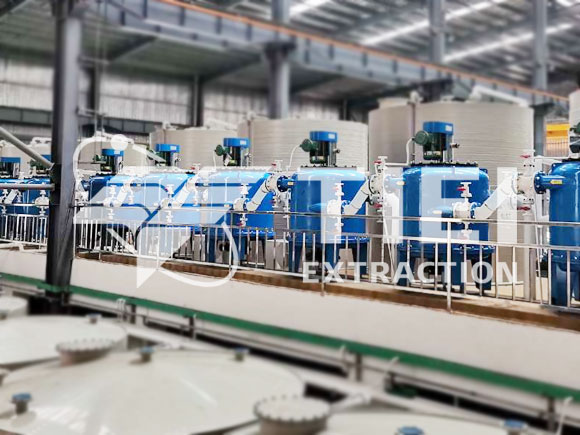

Customer of this company, The raw material liquid of manganese contains impurities such as iron, copper, zinc, calcium, magnesium and sodium, and the processing capacity of the raw material liquid is 40m3 / h. Previously, the customer used the mixing settler as the extraction equipment, which occupied a large area and polluted the environment.

Customer decided to find new high-efficiency environmental protection equipment to replace the mixing settler and finally cooperated with Tiei.