With the maturity of centrifugal extraction technology and the increasing demand for automation in the API industry, centrifugal extractors have gradually replaced traditional gravity extraction equipment and become the main body of extraction equipment due to their advantages of high extraction efficiency, closed and continuous operation, low solvent consumption, high degree of automation, large processing capacity, and small space occupation. And the centrifugal solvent extraction process formed as the core has also been increasingly widely used.

According to the way of adding the extractant, centrifugal solvent extraction can be divided into cross-flow extraction and counter-current extraction.

Among them, counter current extraction is widely used in the separation process of organic phase and aqueous phase due to its high extraction agent utilization rate and low consumption, such as corimycin, penicillin, tocopherol, Ginkgo biloba active ingredients (flavonoids and terpene lactones, terpene lactones include bilobalide and ginkgolide), tea polyphenols, swainsonine, chlorogenic acid, hydrocortisone and other extractions.

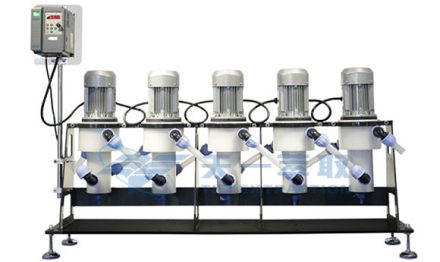

As a provider of liquid-liquid extraction technology and equipment, Zhengzhou Tiei Extraction’s core product, the new generation CWL-M series centrifugal extractor, has been widely recognized by the market for many years, and can meet the needs of continuous counter-current extraction and cross-flow extraction. Compared with traditional extraction equipment, it has irreplaceable and outstanding advantages:

- Simple and convenient operation: The centrifugal extraction machine can operate intermittently or continuously. The operation is simple and convenient, the mixing and separation speed is fast, and the stage retention amount is small.

- The centrifugal extraction machine has a larger processing capacity and is more energy-saving.

- The centrifugal extractor uses perfluoropolymer materials, which can withstand corrosion from strong acids (hydrochloric acid, mixed acids, etc.).

- At the same time, the centrifugal extraction machine has a variety of optional mixing structures, has high separation effect, and can be applied to systems that are easy to emulsify.

Utilizing the characteristics of the centrifugal extractor, which combines powerful mixing and high-speed separation and phase separation in one machine, artificial phase separation methods such as traditional mixing tanks and sedimentation tanks in the washing, desalting, and impurity removal processes of raw materials, to achieve airtight, fully automatic and continuous production.

Email: sales@tieiextraction.com