Nickel and cobalt are widely used in the electronic field. With the development of industry, the market prospects of nickel and cobalt are huge. Because the physical and chemical properties of nickel and cobalt are very similar, it is difficult to directly recover them using classic methods such as chemical precipitation or oxidation. They need to be separated in advance.

In the field of nickel and cobalt separation, solvent extraction method is widely used. Nickel cobalt solvent extraction equipment currently uses centrifugal extractors and mixing settlers. Among them, the mixing settlers is a relatively mature technology and is currently used a lot. However, because traditional equipment has problems such as poor phase separation, long clarification time, and entrainment, many manufacturers are now beginning to consider using new centrifugal extractors to replace the original mixing settlers.

The CWL-M centrifugal extractor launched by Tiei Extraction can reduce the amount of liquid material in the equipment and improve the separation efficiency during the extraction of nickel and cobalt. Moreover, when using a centrifugal extraction device to extract nickel and cobalt from the solution, due to the high mixing intensity, the material can reach an equilibrium state in a very short residence time. Compared with the traditional mixing and clarifying tank, the energy consumption is greatly reduced, and the processing capacity is increased. At the same time, the centrifugal extraction device has a small amount of material stored in it, fast phase separation, good effect, and avoids emulsification. Currently, the centrifugal extractor models used in the field of hydrometallurgy include: CWL150-M, CWL250-M, CWL350-M, CWL450-M, CWL550-M, CWL650-M, and CWL950-M.

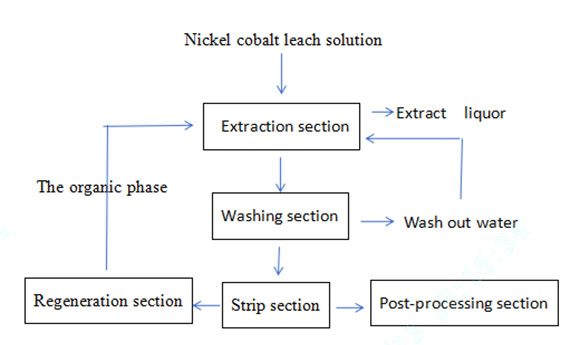

Tiei Extraction CWL-M centrifugal extraction nickel and cobalt process system mainly includes extraction and stripping sections. The specific process flow is:

Our customer's nickel sulfate extraction project uses Zhengzhou Tiei CWL-M series centrifugal extractor. The entire process flow in this project is divided into four sections: extraction, acid washing, stripping, and regeneration. Our centrifugal extractor is used as the core equipment. The extraction efficiency of this equipment is >96%, and the stripping stage efficiency is >94%. It can achieve effective washing and high stripping flow ratio (O/A), which can enrich the cobalt chloride solution to >1209l/, Co/Ni>100000. The extracted nickel sulfate product has high purity, the solvent can be fully recycled, and the environment of the production workshop is greatly improved, which is in line with the national call for energy conservation and environmental protection.

Email: sales@tieiextraction.com