In the fields of food processing, biopharmaceuticals, and fine chemicals, lactic acid is a critical organic acid with steadily growing market demand. However, traditional lactic acid extraction processes face multiple challenges, including low extraction efficiency, high energy consumption, limited product purity, and excessive solvent usage. These bottlenecks significantly restrict production efficiency and hinder the sustainable development of lactic acid producers.

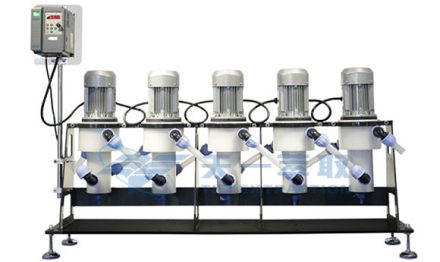

Zhengzhou Tiei Extraction has a deep understanding of these industry challenges and has developed the CWL-M series centrifugal extractor, delivering a disruptive innovation for lactic acid extraction processes.

Technological Breakthrough: Working Principle and Process Flow of the CWL-M Centrifugal Extractor

The CWL-M centrifugal extractor adopts a multi-stage counter-current extraction process. Through a precisely engineered internal structure, rapid mixing and separation of two liquid phases are achieved within a high-speed rotating centrifugal force field.

1.Feed stage: The lactic-acid-containing solution and the extractant are fed separately into the drum.

2.Mixing and mass transfer: Under centrifugal force, the two liquid phases are forcibly mixed, forming ultra-thin liquid films and micron-scale droplets, greatly increasing the interfacial area for mass transfer.

3.Rapid phase separation: Leveraging the density difference between the two phases, millisecond-level separation is achieved under intense centrifugal force.

4.Continuous discharge: The extract phase and raffinate phase are continuously discharged through separate outlets.

Core Advantages of the CWL-M Centrifugal Extractor

1.High Efficiency and Energy Saving with Significant Cost Reduction

Compared with conventional extraction equipment, the CWL-M centrifugal extractor delivers substantial economic benefits:

Extraction efficiency increased by more than 40%

Solvent holdup reduced by up to 60%, significantly lowering solvent consumption and recovery costs

Continuous operation minimizes labor requirements and time costs associated with batch processing

2.Outstanding Extraction Performance

Single-stage extraction efficiency exceeding 90%; overall extraction rate surpasses 99.5% in multi-stage configurations

Significantly improved product purity, meeting pharmaceutical-grade and food-grade lactic acid standards

Treated lactic acid concentration can reach over 85%, reducing downstream concentration and evaporation energy consumption

3.Intelligent and Automated Operation

Equipped with a PLC-based automatic control system for one-touch start-up and simplified operation

Real-time monitoring of operating parameters with automatic adjustment of rotational speed and flow rates

Built-in fault warning and automatic protection functions to ensure safe and stable operation

4.Environmentally Friendly and Safe Design

Fully enclosed structure ensures zero solvent evaporation, providing a safe operating environment

Construction materials comply with food-grade and GMP standards, eliminating contamination risks

Compact footprint, occupying only one-third of the space required by traditional extraction equipment

5.High Process Flexibility

Wide processing capacity range, covering applications from laboratory scale to full industrial production

Compatible with lactic acid feed solutions of varying concentrations and sources

Optional equipment materials available, offering excellent corrosion resistance

Application Case: Outstanding Performance of the CWL-M Centrifugal Extractor in Lactic Acid Production

A large-scale lactic acid producer using a conventional extraction process faced the following challenges:

Extraction efficiency of only 65%, with a significant amount of lactic acid remaining in the wastewater

High solvent consumption, with annual costs exceeding RMB 3 million

Unstable batch production, resulting in fluctuations in product quality

After the Introduction of the CWL-M Centrifugal Extractor:

Lactic acid extraction efficiency consistently achieved over 99.2%

Solvent consumption reduced by 58%, delivering annual cost savings of RMB 1.74 million

Product purity increased from 95% to 99.5%, meeting pharmaceutical-grade standards

Enabled 24-hour continuous operation, increasing overall production capacity by 120%

The CWL-M centrifugal extractor is not just an extraction equipment, but a comprehensive upgrade solution for lactic acid extraction processes. It represents the future direction of efficiency, energy saving, and environmental protection, helping companies reduce production costs, enhance product competitiveness, and achieve sustainable development goals.

Email: sales@tieiextraction.com

Whatsapp: +86 19069612820