Solvent Extraction Process Requirements

- Extractant Selection

It needs to have high lithium selectivity, preferentially extract lithium ions (Li⁺), and avoid co-extraction of impurities (such as Na⁺, K⁺, Mg²⁺, Ca²⁺).

Commonly used extractants:

Crown ethers (such as 12-crown-4): have specific complexing ability for Li⁺.

Tributyl phosphate (TBP): synergistically extracts Li⁺ with FeCl₃.

β-diketones (such as LIX series): bind to Li⁺ at a specific pH. - Pretreatment of feed liquid

pH adjustment: ensure that the feed liquid is in the optimal activity range of the extractant (such as pH 6-8).

Impurity removal: pre-remove highly interfering ions such as Mg²⁺ and Ca²⁺ through chemical precipitation, ion exchange or adsorption. - Phase separation conditions

Optimize mixing intensity and time to ensure full contact between the two phases (aqueous phase/organic phase).

Add salting agent (such as NaCl) or surfactant to accelerate the phase separation process. - Stripping system

Select a suitable stripping agent (such as dilute hydrochloric acid, sulfuric acid) to efficiently release Li⁺ and regenerate the organic phase.

Solvent Extraction Process for Lithium Extraction

- Pretreatment

Filter to remove suspended matter, adjust the pH of brine/liquid, and remove Mg²⁺ and Ca²⁺ by chemical precipitation. - Extraction

Mixing: Mix the pretreated liquid with the organic phase containing the extractant (such as TBP diluted with kerosene) in proportion, and Li⁺ is selectively extracted into the organic phase.

Phase separation: Stand or centrifuge to obtain the lithium-loaded organic phase and the lithium-poor aqueous phase. - Washing

Wash the organic phase with pure water or low acid solution to remove co-extracted impurities such as Na⁺ and K⁺. - Stripping

Mix the lithium-loaded organic phase with an acidic stripping solution (such as 0.5-1M HCl), transfer Li⁺ into the aqueous phase, and regenerate the organic phase for recycling. - Lithium recovery

The stripping solution is concentrated, precipitated (such as adding Na₂CO₃ to generate Li₂CO₃) or electrolyzed to obtain a high-purity lithium product.

Advantages of Solvent Extraction of Lithium

- High selectivity

Applicable to brine with high magnesium-lithium ratio (Mg/Li > 100:1), which is difficult to treat by traditional precipitation method. - Low energy consumption

Compared with salt field evaporation method (which takes several months), the extraction method can be operated continuously, shortening the cycle and reducing energy consumption. - Environmentally friendly

The organic phase can be recycled to reduce reagent consumption and wastewater discharge. - Flexibility

It can handle complex raw materials (such as waste lithium battery leachate, low-grade ore leachate). - High recovery rate and purity

The lithium recovery rate can reach more than 90%, and the stripping solution can be simply purified to obtain battery-grade lithium carbonate (purity ≥99.5%).

Through solvent extraction, the lithium extraction process has shown significant advantages in the processing of complex raw materials. In the future, with the development of new extraction agents (such as ionic liquids), its economy and environmental protection will be further improved.

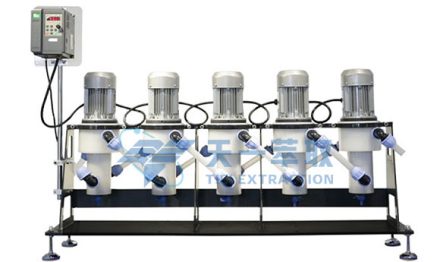

For lithium extraction equipment, you can choose Tiei Extraction CWL-M centrifugal extractor, a new type of efficient extraction and separation equipment, which uses high-speed centrifugal force to separate two immiscible liquids with different densities. The CWL-M centrifugal extractor developed and produced by Zhengzhou Tiei Extraction Technology Co., Ltd. has a wide range of applications in the extraction of metal elements in the field of hydrometallurgy, and the process is also very mature. A variety of models can meet the different production needs of customers.

For more details, welcome consult Tiei Extraction.

Email: sales@tieiextraction.com

Whatsapp: +86 19069612820