In the fields of hydrometallurgy, chemical separation, and environmental resource recovery, the selection of liquid-liquid extraction equipment directly impacts production efficiency and economic benefits. As two mainstream extraction equipment, the mixer settler and the centrifugal extractor often cause confusion among professionals due to differences in working principles and performance characteristics. Technical experts from Zhengzhou Tiei Extraction will systematically analyze the core technical differences between the two, providing professional guidance for equipment selection.

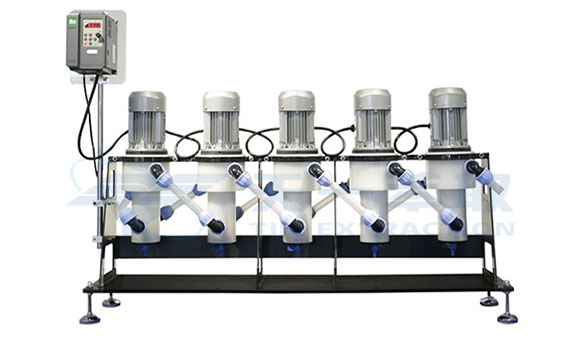

Mixer Settler, as a classic gravity separation equipment, relies on the density difference between two-phase liquids to achieve natural stratification. The equipment is typically divided into a mixing chamber and a clarification chamber in a 1:3 ratio. The feed liquid undergoes mass transfer in the mixing chamber under the stirring action, and then overflows into the clarification chamber for gravity sedimentation and separation. Mixer settler is commonly made of PMMA (acrylic) or PP (polypropylene) materials, offering a simple structure, stable operation, flexible inter-stage configuration, and relatively low initial investment. However, its reliance on gravity separation results in slow phase separation, large equipment footprint, and difficulty in achieving automated continuous operation.

Centrifugal Extractor represents the development direction of efficient separation technology. Through the high-speed rotational centrifugal force field, it accelerates the two-phase separation process, the denser heavy phase moves towards the drum wall and is discharged out, while the lighter phase with a lower density, gathers towards the center and is extracted. Taking the CWL-M series centrifugal extractor launched by Zhengzhou Tiei Extraction Technology Co., Ltd. as an example, its drum is made of perfluorinated materials, and the piping is made of PVDF, offering excellent resistance to strong acid and alkali corrosion. The CWL-M series centrifugal extractor demonstrates significant advantages in performance: rapid phase separation, high single-stage extraction efficiency, compact structure, reducing the footprint by more than 70%, significantly reduced energy consumption, with operational power consumption only 1/10 to 1/3 of traditional equipment, and it supports fully automated continuous operation, greatly reducing the need for manual intervention.

The centrifugal extractor is gradually replacing the traditional mixer settler primarily due to three core advantages:

- 1.Revolutionary improvement in separation efficiency. Separation under a centrifugal force field reduces the phase separation time from hours to minutes or even seconds, and the separation is more thorough, effectively solving the problem of entrainment.

- 2.Significant optimization of lifecycle costs. The centrifugal extractor not only consumes very little power but also greatly reduces maintenance frequency and costs through optimized design (such as eliminating bottom mechanical seals and bearings), while improving the utilization rate of the extracting agent.

- 3.Space and automation empowerment. The modular design significantly saves factory space and provides a hardware foundation for achieving fully automated and intelligent production processes.

In response to the issues of corrosion, high failure rates, and high energy consumption found in some traditional centrifugal equipment on the market, Zhengzhou Tiei Extraction has achieved key breakthroughs through continuous technological innovation in the CWL-M series centrifugal extractor: using special corrosion-resistant materials to extend the equipment's lifespan; innovating structural design to eliminate wear-prone components and reduce maintenance costs; optimizing fluid dynamics and drive systems to achieve a leap in energy efficiency.

When selecting extraction equipment, it is essential to consider process requirements, handling capacity, material characteristics, and long-term operational costs. For modern production lines that prioritize efficiency, continuity, energy saving, and space optimization, centrifugal extraction technology, represented by the CWL-M seriescentrifugal extractor, has become a more forward-thinking choice.

Email: sales@tieiextraction.com

Whatsapp: +86 19069612820