In hydrometallurgy, electroplating, titanium dioxide production, and petrochemical refining industries, large volumes of waste sulfuric acid with low concentration and high impurity content are generated. If such waste acid is directly disposed of, it not only incurs high hazardous waste treatment costs, but also results in a tremendous waste of resources and poses a serious threat to the environment.

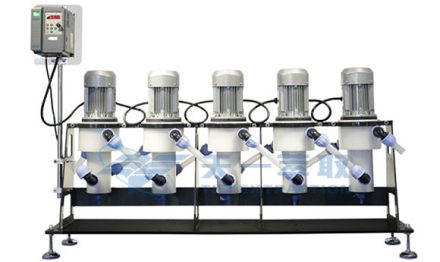

Traditional waste sulfuric acid treatment methods, such as neutralization and concentration, generally suffer from drawbacks including long process flows, high energy consumption, large amounts of solid waste generation, and the inability to realize resource recovery. Today, coupled extraction method, an advanced technology that is efficient, clean, and resource-efficient, is becoming a new favorite in the industry due to its significant advantages. The core equipment for this process is the Zhengzhou Tiei Extraction CWL-M series centrifugal extractor.

Centrifugal Extractor Working Principle

Mixing

The waste acid aqueous phase and the organic extractant are pumped into the mixing zone of the centrifugal extractor drum in a certain proportion. Driven by the high-speed rotation of the drum, the two phases are violently sheared and mixed, forming a large mass transfer surface area, allowing impurities to be quickly transferred from the aqueous phase to the organic phase.

Separation

Under the action of powerful centrifugal force, the two immiscible liquids with different densities are rapidly and thoroughly separated. The heavy phase (purified sulfuric acid) flows outward along the rotating wall, while the light phase (loaded organic phase) gathers toward the center, and flows out through different outlets.

Advantages of Centrifugal Extractor in Waste Sulfuric Acid Treatment

1.High Efficiency Mass Transfer:Intense mixing ensures a much higher mass transfer rate compared with traditional stirred tanks or packed columns. Fewer stages are required, resulting in smaller equipment size.

2.Rapid Phase Separation:Centrifugal force effectively overcomes the challenges of emulsification and small density differences, enabling fast separation with residence times measured in seconds.

3.Strong Adaptability:Particularly suitable for systems prone to emulsification, containing solid suspensions, or having small density differences between phases — all of which are common characteristics of complex waste sulfuric acid.

4.Sealed Operation:Fully enclosed operation prevents the leakage of volatile organic compounds (VOCs) and acid mist, creating a safer and more environmentally friendly workplace.

5.Continuous and Automated:Capable of 24-hour continuous feed operation. Easily integrated with DCS systems for high automation, reducing labor demand.

6.Minimal Hold-Up Volume:The centrifugal extractor holds only a small amount of liquid within the equipment, lowering the inventory of hazardous materials in the system and reducing safety risks.

Process Flow of Coupled Extraction for Waste Sulfuric Acid Treatment

- Pretreatment

The waste sulfuric acid first undergoes simple filtration or sedimentation to remove most solid suspensions, protecting the pumps and rotor of the subsequent equipment centrifugal extractor. - Extraction Section

The pretreated waste acid and the regenerated clean extractant are pumped proportionally into the first stage of a multistage CWL-M centrifugal extractor system arranged in series.

Through counter-current contact between the two phases, impurities are gradually transferred into the organic phase.

The aqueous phase flows from the final stage is purified sulfuric acid, which is then sent either to a concentration unit or directly reused. - Stripping Section

The impurity-loaded organic phase flows from the first stage of the extraction section is fed into another set of CWL-M centrifugal extractors (the stripping section).

Here, the loaded organic phase contacts the stripping agent (such as water), transferring impurities into the aqueous phase.

The regenerated clean extractant is then recycled back into the extraction section for reuse. - Post-Treatment

Acid Recovery: The purified sulfuric acid is concentrated in an evaporator to the required concentration.

Impurity Concentration: The aqueous phase generated in the stripping stage, containing a relatively small volume of impurities, can undergo further treatment (such as recovery of valuable substances, incineration, or biological treatment).

Facing increasingly stringent environmental regulations and the continuous rise of disposal costs, waste sulfuric acid treatment has shifted from being a mere “cost center” to a potential “value center.” With its outstanding features of high efficiency, cost-effectiveness, and environmental friendliness, the CWL-M centrifugal extractor coupled-extraction technology is emerging as a benchmark solution for the resourceful treatment of industrial waste acid.

Email: sales@tieiextraction.com

Whatsapp: +86 19069612820