The main forms of titanium in the earth's crust are titanium dioxide and titanate, and usually coexist with fe, ca, mg, si, al, mn and rare earth elements. According to statistics, there are more than 140 kinds of titanium minerals, but only such as Several types of ilmenite, rutile, white titanium, anatase, brookite and ferrite have mining value. In addition to the processing and utilization of titanium-containing minerals and titanium, the extraction and recovery of titanium from solid materials such as ore, tailings and tailings, and acid solutions is of great practical significance for the comprehensive utilization of resources and clean production in the titanium industry.

The extraction of titanium usually transfers titanium into the liquid phase and extracts it from the acid solution. The hydrolysis of titanium liquid has its particularity, which can make hydrated titanium dioxide precipitate, while other impurity ions remain in the system, so as to separate titanium dioxide from soluble impurities in titanium liquid, which is currently industrial production from titanium liquid. The only way to get titanium dioxide. However, in the feed liquid for leaching and extracting titanium from ores, tailings and tailings and extracting titanium from acid solutions such as waste acid produced by titanium dioxide, the component concentration of titanium is generally low (calculated by tio2, generally 5~30g /l), the concentration of titanium cannot be recovered by hydrolysis, which makes it difficult to recover this part of titanium. Therefore, it has important research value for the extraction and recovery of titanium in acid solution.

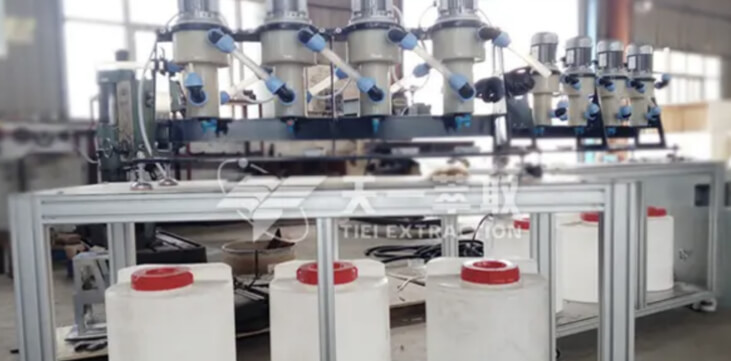

- For acid solutions with low concentration of titanium (mainly sulfuric acid solution or hydrochloric acid solution), make full use of the combination of organic phosphonic acid extractant and amine extractant to produce a synergistic extraction effect to selectively extract titanium;

- Use organic phosphonic acid extractant and amine extractant to extract titanium, and the supported organic phase of titanium can be effectively back-extracted with naoh solution;

- Back-extract the titanium-loaded organic phase with naoh solution, back-extract and filter to obtain back-extracted titanium slag, and remove the residual naoh by "roasting-washing" of back-extraction titanium slag to obtain titanium-rich material with high tio2 content, filtrate and dealkalized washing solution After adding naoh, it can be recycled as a back-extraction agent for titanium;

- The regenerated organic phase of titanium after stripping with sulfuric acid or hydrochloric acid solution can be returned to the extraction operation of titanium for recycling;

- For the titanium resources of half-baked scandium, scandium can be extracted and enriched into titanium-rich materials at the same time, and scandium can be recovered from the further processing and utilization of titanium-rich materials;

- This process solves the problem of selective separation and enrichment of titanium in acid solution, as well as the problem of difficult back-extraction of titanium in other extraction processes, and realizes the recovery of lower concentration titanium in acid solution. It has the characteristics of high enrichment ratio, complete separation, low production cost and no pollution.