Tiei Extraction has developed liquid / liquid centrifugal extractors, from laboratory to industrial production scale designed for the requirements of the chemical, fine chemical, and pharmaceutical industries.

Tiei Extraction Liquid-Liquid Extraction Centrifuges and Equipment

Liquid-Liquid Extraction centrifugal extractors have been used widely in industries such as the pharmaceutical, fine chemical, food products, nuclear…

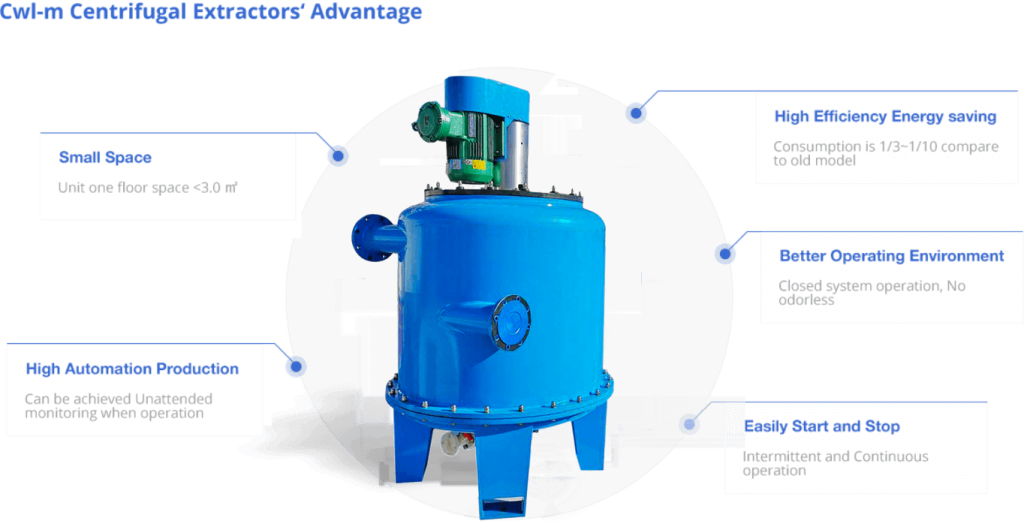

These monostage centrifugal extractors, also known as centrifugal contactors, annular centrifugal contactors, or liquid / liquid extraction centrifuges offer the following advantages and benefits:

Counter-current continuous extraction for maximum efficiency

Direct motor coupling to the main shaft

Short retention time and low liquid holdup

Well adapted to batch or continuous operation

Optional [Clean in place] systems

for multi-product pharmaceutical processing

No Bottom Bearing in process area

Centrifugal force provides efficient phase separation

Unique construction for corrosive applications

Unattended operation

High throughputs achieved in compact machine

High extraction efficiency typically greater than 98% theoretical

Connected in series to achieve required number of stages

No interstage pumps required

Rapid operational equilibrium

Laboratory, pilot, and industrial scale machines available

Cart or skid mounted systems for easy portability

Rental equipment available

Internal recycling systems

Forward extraction, back extraction, scrubbing, water-washing, closed loop extraction, fractional extraction

Liquid/Liquid Centrifugal Separators

Tiei Extraction centrifugal liquid / liquid separators have been used widely in industries such as the pharmaceutical, fine chemical, food products, oil / water separations…..

Tiei Extraction focus on being Mixing And Separation Solution Provider.