In the fields of fragrances, pharmaceuticals (especially penicillin G), and agrochemicals, phenylacetic acid serves as an indispensable key intermediate. Its purification and recovery processes directly affect the quality of the final product, overall production costs, and enterprise efficiency. Traditional extraction methods for phenylacetic acid are often plagued by low efficiency, high solvent consumption, emulsification issues, and large space requirements, becoming a major bottleneck for enterprises seeking quality improvement and cost reduction.

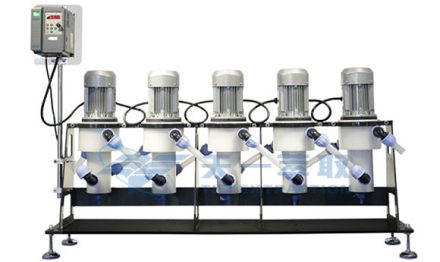

The core product of Zhengzhou Tiei Extraction Technology Co., Ltd., the CWL-M series centrifugal extractor, with its revolutionary working principle and excellent performance, provides a new, efficient, energy-saving and stable solution for the extraction and separation of phenylacetic acid.

Traditional Pain Points in Phenylacetic Acid Extraction

1.Low efficiency, high stage requirement: Conventional column equipment requires a large number of theoretical stages, resulting in bulky equipment and long extraction times.

2.Prone to emulsification: Under strong agitation, phenylacetic acid systems tend to form stable emulsions, making phase separation difficult and severely impacting production continuity and yield.

3.High solvent loss: Long residence time and large interfacial area lead to significant evaporation losses of volatile organic solvents (VOCs), increasing both costs and environmental pressure.

4.Limited operational flexibility: Sensitive to flow fluctuations, with difficult adjustment of processing capacity, making it hard to adapt to production changes.

Efficient Extraction of Phenylacetic Acid with Centrifugal Extractor

The CWL-M centrifugal extractor utilizes the powerful centrifugal force generated by high-speed rotation to achieve thorough mixing and mass transfer of two immiscible liquid phases with different specific gravities in a very short time, achieving rapid and thorough phase separation. This perfectly solves the aforementioned challenges.

The two liquid phases undergo intense yet precise mixing within the high-speed rotating drum, achieving instantaneous mass transfer. The powerful centrifugal force then flings the mixed liquid toward the drum wall, rapidly separating it into the light and heavy phases, which are then discharged through separate flow channels. The entire process is continuous, sealed, and automated.

- Exceptional Efficiency, Streamlined Process

With extremely high single-stage extraction efficiency, a single unit can often accomplish the work of multiple traditional extraction column stages. This greatly simplifies the process flow and saves valuable plant space. - Complete Solution to Emulsification

The powerful centrifugal force enforces phase separation, completely eliminating emulsification issues caused by material properties or operational fluctuations. This ensures continuous and stable production while improving product recovery rates. - Ultra-Low Solvent Loss, Cost Reduction and Efficiency Boost

The fully enclosed operating system minimizes contact between solvents and air, effectively suppressing VOC evaporation. This not only reduces production costs but also alleviates the burden of subsequent environmental treatment. - Short Residence Time, Ideal for Heat-Sensitive Materials

Materials remain inside the equipment for an extremely short time, making it especially suitable for phenylacetic acid and other systems sensitive to residence time. This minimizes side reactions and ensures product quality. - High Operational Flexibility and Automation

Processing capacity can be flexibly adjusted within a certain range to match varying production loads. The centrifugal extractor offers quick start-up and shutdown, convenient integration with plant operations, and easy implementation of DCS automated control—reducing manual intervention. - Reduced Investment and Operating Costs

With its compact size, the equipment lowers infrastructure investment. Minimal solvent holdup reduces both safety risks and production costs. Easy maintenance and relatively low energy consumption further contribute to outstanding overall economic benefits.

Successful Application Cases

The CWL-M Series Centrifugal Extractor has already been successfully applied in phenylacetic acid production and wastewater recovery projects at several well-known pharmaceutical and chemical enterprises in China.

Operational data demonstrate that:

Extraction efficiency exceeds 95%;

Solvent consumption reduced by approximately 20–30% compared with traditional methods;

Production line footprint reduced by more than 60%;

Achieves continuous, stable, and clean production, with exceptionally high customer satisfaction.

In the face of increasingly fierce market competition and stringent environmental regulations, upgrading extraction processes has become an inevitable trend. The CWL-M Centrifugal Extractor from Zhengzhou Tiei Extraction Technology offers a new pathway toward efficient, energy-saving, and environmentally friendly phenylacetic acid production with its cutting-edge technological advantages. We not only provide advanced equipment, but also deliver comprehensive process solutions and full lifecycle technical services to support your success.

Email: sales@tieiextraction.com

Whatsapp: +86 19069612820