In the field of fine chemicals and pharmaceutical intermediates production, the efficient separation of n-hexane and n-butyl ether has long been a critical factor affecting product quality and production efficiency. As market competition intensifies, traditional reactor-based processes can no longer meet the modern industry’s growing demands for efficiency, purity, and environmental sustainability. This article explores the limitations of traditional separation methods and introduces how centrifugal extraction technology offers enterprises an innovative and effective solution.

Multiple Challenges in Traditional Separation Processes

Traditional reactor-based separation methods have exposed numerous issues over years of operation, severely limiting the sustainable development of enterprises.

The first major issue is the efficiency bottleneck. The intermittent operation mode of a single batch of "feeding-stirring-standing-discharging" takes up to 4-5 hours, and the daily processing capacity is limited to 2-3 tons. This low-efficiency production mode makes it difficult for companies to respond promptly to market demand during peak order periods. For example, one dye intermediate manufacturer reportedly lost 30% of potential orders due to insufficient production capacity.

In terms of separation quality, the similar densities of n-hexane (0.659 g/cm³) and n-butyl ether (0.796 g/cm³) make it easy for emulsification to occur when relying solely on gravity settling. As a result, product purity fluctuates between 90% and 95%, and impurity levels often exceed the critical limit of 100 ppm. Some export orders have even been rejected due to substandard quality, causing significant economic losses for enterprises.

Moreover, traditional processes face serious cost control challenges. High-power stirring equipment and steam heating systems lead to excessive energy consumption, while solvent residues can reach as high as 10%. According to company data, annual solvent losses from n-hexane alone can exceed 500,000 RMB. Under increasingly stringent environmental regulations, poor sealing performance in traditional equipment often results in VOC concentrations as high as 200 ppm, increasing wastewater treatment costs by 40%. Many enterprises consequently face the risk of environmental penalties or even forced shutdowns for rectification.

Innovative Breakthroughs in Centrifugal Extraction Technology

The emergence of the centrifugal extractor has provided a comprehensive technical solution to the challenges mentioned above. Based on the principle of centrifugal force–enhanced mass transfer, this technology achieves a qualitative leap in separation efficiency through engineering innovation.

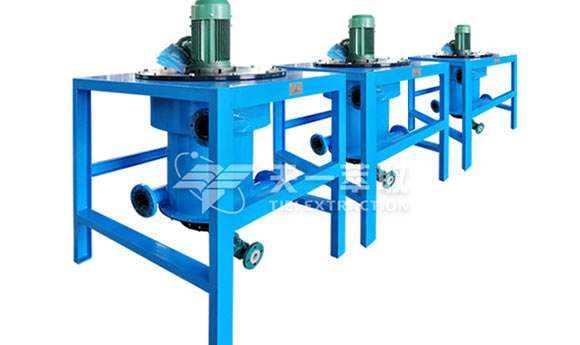

In the design of the CWL-M centrifugal extractor by Zhengzhou Tiei Extraction, continuous production stands out as one of its core advantages. The equipment adopts an integrated mixing–separation structure, enabling real-time feed and discharge operations and supporting 24-hour continuous running, completely transforming the traditional batch production mode.

A major breakthrough lies in the significant improvement in separation precision. With a rotor speed ranging from 1,500 to 3,350 rpm, the machine generates thousands of times the force of gravity, rapidly breaking emulsions. In practical applications, when the rotation speed is optimized to 1,500 rpm, separation efficiency exceeds 95%, n-hexane residue drops below 1%, and product purity remains consistently above 99%.

From an economic perspective, the technology delivers remarkable benefits. By eliminating the need for long-term heating and stirring, energy consumption is reduced to one-third of that of traditional reactors. Its modular design ensures a solvent recovery rate above 98%, saving more than 400,000 RMB per year in solvent costs. Meanwhile, the fully sealed system keeps VOC concentrations strictly below 30 ppm, significantly reduces solvent content in post-extraction wastewater, and lowers treatment costs by about 35%, helping enterprises easily meet environmental compliance standards.

Industrial Application and Equipment Selection

A technological upgrade case from a fine chemical enterprise fully demonstrates the practical value of centrifugal extraction technology. In the project aimed at separating n-hexane and n-butyl ether mixtures, the adoption of professional centrifugal extraction equipment yielded remarkable results: processing capacity increased from 0.6 m³/h to 5 m³/h, fully meeting the needs of a 10,000-ton-scale production line; product quality improved significantly, with impurity levels reduced from 80 ppm to 8 ppm. Meanwhile, energy consumption decreased by 30%, solvent loss was reduced by 80%, and the annual comprehensive economic benefit increased by more than 2 million RMB.

In terms of equipment selection, enterprises can flexibly choose models based on actual requirements. During the experimental stage, small-scale units can be used for parameter optimization; for pilot and full-scale production, larger-capacity models can be adopted to meet different throughput demands. Key operating parameters include a feed flow rate between 0.6–5 m³/h, rotational speed adjusted to 1,500–3,000 rpm depending on the degree of emulsification, and a phase ratio maintained between 1:10 and 10:1 to achieve optimal mass transfer efficiency.

Zhengzhou Tiei Extraction Technology Co., Ltd. has been deeply engaged in the field of centrifugal extraction for many years. The CWL-M series centrifugal extractor has been successfully applied in numerous industrial scenarios, creating significant economic and environmental benefits for customers. In the context of the chemical industry’s transformation and upgrading, adopting advanced and efficient separation technologies has become a key measure for enterprises to enhance competitiveness.

Email: sales@tieiextraction.com

Whatsapp: +86 19069612820