- About Us

- Equipment

- Solution

- Cases

- News

- Service

- Contact us

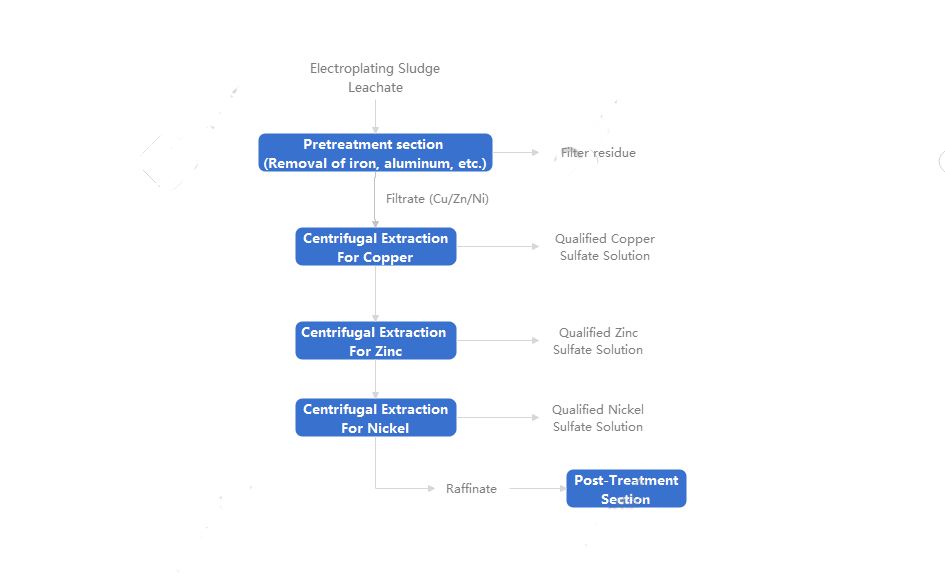

Electroplating sludge is a solid waste generated during the treatment of electroplating wastewater. It contains some heavy metals such as iron, nickel, chromium, copper, zinc, etc. It has a high water content, during the stacking process, the precious metals in it are easy to seep into the water and soil, causing serious secondary pollution. The various metal components contained in electroplating sludge are often higher in grade than metal-rich ores, and are also a cheap secondary renewable resource.

At present, there are many studies on heavy metal recovery from different types of electroplating sludge, such as leaching electroplating sludge by ammonia leaching or acid leaching to obtain heavy metal ions or complex metal ions, and then recovering metal ions by distributed precipitation or solvent extraction. Microbial purification is used to recover chromium and other heavy metals in electroplating sludge. However, there are certain problems in practice, such as overly complicated processes, low metal recovery rates, unstable product quality, and easy secondary pollution. Therefore, from the perspective of metal resource recovery and environmental protection, the development of a new green process for recovering valuable metals from electroplating sludge is the focus of current research.

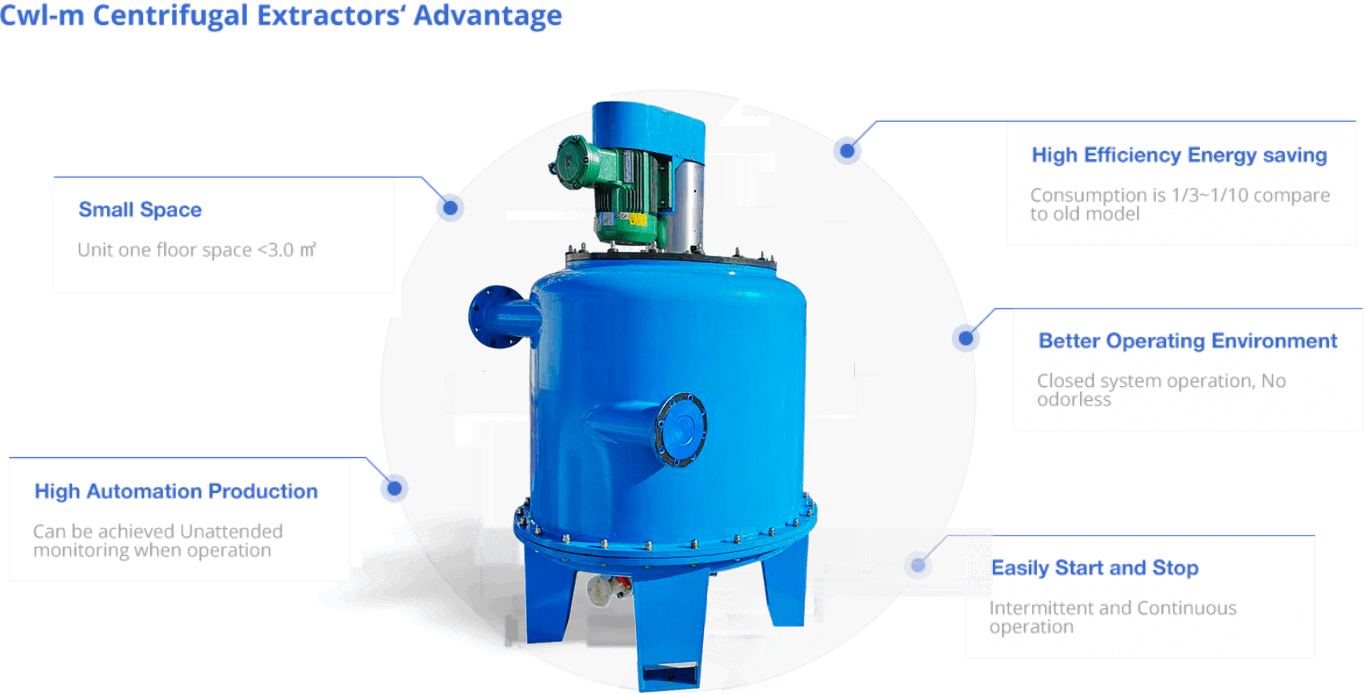

Centrifugal extraction is different from the traditional liquid-liquid extraction method. It is based on the principles of cation exchange and complex extraction in metal extraction, and combined with the new CWL-M extraction equipment to develope the green extraction process. It has the following characteristics:

1.High metal extraction efficiency, up to 99%.

2.Simple process flow, easy to operate.

3.The quality of the stripping solution obtained is stable and can meet different production requirements.

4.The amount of organic solvent residue in the treated water is small, which can reduce the processing pressure of subsequent stages.

5.The extraction equipment occupies a small area and has great processing flexibility.

6.The equipment is sealed and connected, and the operating environment is good, which can avoid secondary pollution.

7.The equipment has a small liquid storage volume, and the investment cost of extracting the organic phase is reduced.

8.The main extraction equipment is made of perfluorinated materials, which can meet a variety of liquid systems.

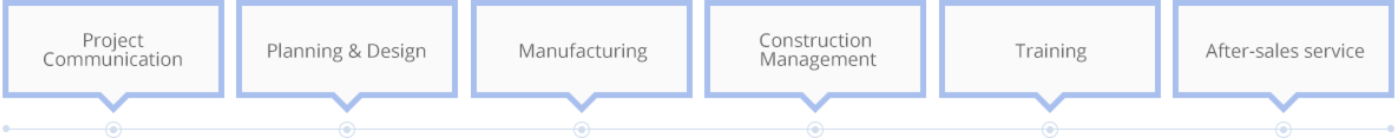

Supporting One-stop service:

Project communication, planning, scheme design, equipment manufacturing, process operating, and construction management, training and project after-sales service.

Tiei extraction recommend LABORATORY EXTRACTION EQUIPMENT, to help you understand the extraction equipment, to verify technolgoy process and equipment characteristics.

Also you can view relevant CUSTOMER CASES, EXTRACTION EQUIPMENT SOLUTIONS and RESEARCH TRENDS and browse all extraction equipment.

Leave your questions and we will get in touch with you as soon as possible

Leave your questions and we will get in touch with you as soon as possible