H-acid is an important intermediate in the dye industry. The wastewater generated during its production process is extremely complex and has the following characteristics:

- High COD: Extremely high organic matter content, COD levels can reach tens of thousands or even hundreds of thousands of mg/L.

- High salinity: Contains large amounts of inorganic salts such as Na₂SO₄, which severely inhibit microbial activity.

- High color and poor biodegradability: Contains bioinhibitory substances such as naphthalene sulfonates, resulting in extremely poor biodegradability (extremely low B/C ratio).

Direct biochemical treatment of this type of wastewater is largely ineffective, while advanced oxidation processes or evaporative crystallization often incur high operating costs and are prone to equipment blockage and secondary pollution. Effective pretreatment, load reduction, and resource recovery have become key bottlenecks hindering green development for businesses.

"Two-step Extraction + Two-step Stripping" Centrifugal Extraction Process

To address these pain points, we have innovatively introduced an integrated pretreatment process combining a two-step extraction and two-step stripping process with a centrifugal extractor. This process is not a simple addition, but rather a systematic engineering optimization based on the principles of mass transfer.

Core Technology Principle: Solvent Extraction

Leveraging the solubility differences between H-acid and its intermediates in the organic and aqueous phases (wastewater), a highly specific extractant is selected to efficiently "capture" and transfer organic matter from the wastewater into the organic phase, achieving the dual goals of wastewater purification and resource recovery. The purified wastewater significantly reduces COD and color, significantly improving biodegradability, laying the foundation for subsequent low-cost biochemical treatment.

Two-step extraction + two-step stripping

Step 1: Two-stage cross-current extraction (two-stage extraction)

Select an efficient extractant and thoroughly mix it with the H-acid wastewater to capture the toxic and colored naphthalene-based organic compounds in the wastewater into the organic phase, achieving initial separation.

Step 2: Two-stage cross-current stripping (two-stage stripping)

The organic-rich extractant is then brought into contact with the stripping solution, allowing the organic compounds to be transferred back into the stripping solution. The extractant can be recycled, and the stripping solution can be further concentrated to produce a water-reducing agent—turning waste into treasure!

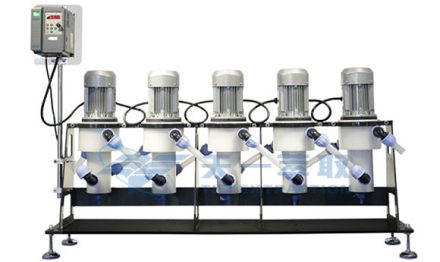

Core Equipment: Centrifugal Extractor

Traditional extraction column, mixer settler and other equipment have problems such as low efficiency, large footprint, easy emulsification, and large liquid holdup when treating H-acid wastewater. Centrifugal extractor is the best choice for this process, with unparalleled advantages:

- Efficient mass transfer and short residence time: High-speed centrifugal force rapidly mixes and separates the two phases, resulting in extremely high mass transfer efficiency and high throughput, making it ideal for continuous, large-scale production.

- Effectively prevent emulsification: Centrifugal force effectively breaks up droplet emulsions, eliminating operational instability caused by three-phase entrainment and emulsion layers, and ensuring effluent quality.

- Small footprint and high degree of automation: The compact equipment enables fully automated closed-loop operation, significantly reducing manual operation and chemical exposure risks.

- Low liquid holdup and high safety: The amount of organic solvent retained in the system is minimal, reducing safety risks and material loss.

Customer Feedback

Our factory used to spend hundreds of thousands of yuan per month just to treat H-acid wastewater. Since adopting the "two extraction, two stripping" process with a CWL-M centrifugal extractor, our costs have been cut in half. Our effluent COD and color levels are now fully up to standard, and we even recover useful raw materials. It's truly a cost-saving and worry-free process, and we even passed our environmental inspections on the first try!

H-acid wastewater treatment is no longer a mere "cost center." Through the "two-step extraction + two-step stripping" centrifugal extraction pretreatment process, it can be transformed into a "resource gold mine" that is eager to be developed. Choosing us means choosing a set of engineering-proven, mature and reliable solutions.

Email: sales@tieiextraction.com

Whatsapp: +86 19069612820