In the field of rare metal metallurgy and advanced material preparation, the separation and extraction of rubidium and cesium has long been recognized as a technical challenge. Traditional methods such as mixer-settler extraction, ion exchange, or precipitation not only involve lengthy processes and excessive reagent consumption, but also suffer from low separation efficiency, becoming a bottleneck for industrial development. The CWL-M series centrifugal extractor, launched by Zhengzhou Tiei Extraction, with its outstanding performance and innovative engineering concept, provides an efficient, energy-saving, and continuously stable solution for the solvent extraction and separation of rubidium and cesium.

Challenges in Rubidium and Cesium Separation

Rubidium and cesium share extremely similar chemical properties, resulting in very low separation factors. Traditional equipment such as mixer-settlers faces multiple drawbacks:

Large holdup: Severe retention of reagents and organic phases leads to high costs and significant safety risks.

Difficult phase separation: Emulsification layers are easily formed, causing long separation times and low efficiency.

Limited continuity: Mostly operated in batch mode, with low automation and unstable product quality.

Large footprint: Achieving multistage counter-current extraction requires massive equipment installations.

Meanwhile, cesium and its compounds are increasingly used in time–frequency standards (atomic clocks), photoelectric detectors, specialty glass, pharmaceuticals and catalysis, and new energy applications. The market demand for high-purity, low-cost cesium salts continues to grow. Overcoming the separation challenge means seizing a tremendous market opportunity.

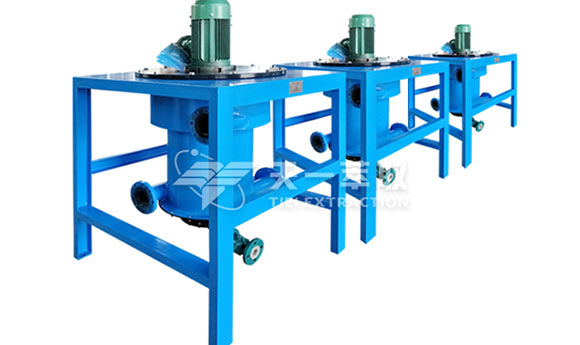

CWL-M Centrifugal Extractor

The CWL-M centrifugal extractor utilizes the powerful centrifugal force generated by the high-speed rotation of the drum driven by a motor, enabling two immiscible liquids of different densities to be efficiently mixed inside the rotor and then instantly separated.

1.Exceptional efficiency, outstanding stage performance

The intense centrifugal force enables ultrafast mixing and near-instant phase separation of the two liquids. Single-stage extraction efficiency can exceed 95%, meaning only a few stages are required to achieve the same effect that would otherwise take dozens of stages with conventional methods—greatly shortening the process flow.

2.Emulsion elimination, strong handling capacity

The powerful centrifugal force completely breaks down stubborn emulsion layers. It shows excellent adaptability to complex feed solutions such as brines and leachates, ensuring continuous and stable production.

3.Minimal holdup, sharply reduced operating costs

The internal holdup is extremely small, which significantly reduces the consumption and capital occupation of expensive extractants (such as t-BAMBP) and feed solutions. This not only lowers operating costs but also enhances production safety.

4.Continuous and automated operation

Enables fully enclosed, continuous counter-current extraction. The system can be seamlessly integrated with DCS or PLC controls, allowing precise regulation of flow rate, rotor speed, and phase ratios. The result is consistent product quality with minimal manual intervention.

5.Modular design, compact footprint

A single unit can achieve multistage functionality, while modular connections allow the easy construction of large-scale production lines. The required footprint is only a fraction (one-tenth to one-few) of that of traditional mixer-settlers, saving significant plant space and infrastructure costs.

6.Environmental and safety benefits

The fully enclosed design effectively prevents the emission of volatile organic compounds (VOCs), protecting the working environment, reducing occupational health risks, and lowering the probability of safety incidents.

Process of Centrifugal Extractor in Extraction and Separation of Rubidium and Cesium

Taking the separation of cesium from lepidolite leachate as an example:

1.Feed preparation: The leachate is purified to remove impurities and then adjusted to the appropriate pH (strongly alkaline).

2.Extraction stage: The feed solution and organic phase (t-BAMBP/diluent) are pumped in a set ratio into a multistage counter-current extraction system composed of CWL-M centrifugal extractors. Cs⁺ is selectively extracted into the organic phase.

3.Scrubbing stage: The loaded organic phase enters the scrubbing section, where trace co-extracted impurities such as Rb⁺ and K⁺ are removed.

4.Stripping stage: The purified loaded organic phase is fed into the stripping section, where it contacts dilute hydrochloric acid to produce a high-purity cesium chloride solution.

5.Organic phase regeneration: The stripped organic phase is regenerated by alkaline washing and then recycled back to the extraction stage.

6.Rubidium recovery: The raffinate (containing Rb⁺) can be sent to another extraction system or treated by other methods to recover rubidium.

For enterprises determined to break through the capacity and cost bottlenecks in rubidium and cesium separation, choosing advanced production equipment is the key to success. The CWL-M centrifugal extractor is not merely an equipment upgrade—it represents a fundamental transformation of traditional production processes. It delivers higher efficiency, lower costs, superior product quality, and greener, safer operations, making it a powerful tool for seizing the commanding heights of the rare metals market.

Email: sales@tieiextraction.com

Whatsapp: +86 19069612820