Benzoic acid, also known as benzoic acid, is widely used in medicine, food, chemical industry, etc. It can be used to prepare a variety of plasticizers, etc. Due to the low cost of benzoic acid, its downstream product sodium benzoate is still the preferred preservative variety. For example, it is used as a preservative and mildew preventer in mosquito coils and Chinese herbal medicine syrups, as a corrosion inhibitor in automobile antifreeze, and as a catalyst in the printing and dyeing industry.

Industrial Production Method of Benzoic Acid and Wastewater Discharge

The industrial production method of benzoic acid is mainly based on the toluene liquid phase air oxidation method. Since this process uses cobalt salt or manganese salt as a catalyst and acetic acid as a solvent, it has the advantages of mature technology, mild reaction conditions, and less waste, and is still the main production route for benzoic acid.

The wastewater produced by the toluene liquid phase air oxidation process is a slightly yellow transparent liquid, the main components of which are benzoic acid and acetic acid, with a pH value between 1.8-2.1 and a chemical oxygen demand (CODcr) of about 20,000 mg/L or more.

Benzoic Acid Wastewater Treatment Process Case

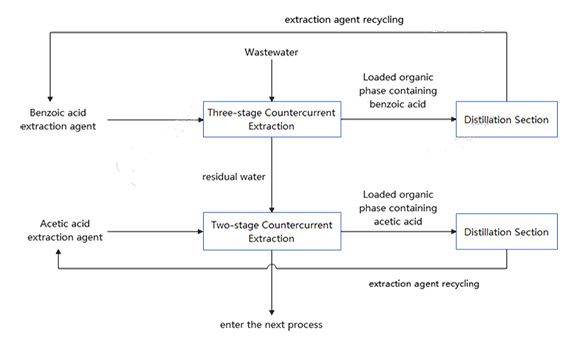

The benzoic acid content in the process wastewater of a certain enterprise producing benzoic acid by toluene liquid phase oxidation method is 0.314mol/L, the acetic acid content is 0.25mol/L, the pH value is 2.03, and the chemical oxygen demand (CODcr) is 23270mg/L. We adopted step-by-step extraction to recover benzoic acid and acetic acid. After three-stage countercurrent extraction, the recovery rate of benzoic acid is above 99%, and the recovery rate of acetic acid is about 95% after two-stage countercurrent extraction of acetic acid.

Email: sales@tieiextraction.com

Whatsapp: +86 19069612820