Centrifugal extractor and mixer settler are both common extraction equipment, mainly used for liquid liquid extraction and separation, and can be applied to extraction operations in many fields such as chemical industry, environmental protection, hydrometallurgy, pharmaceuticals, food, etc. How to choose the right extraction equipment, customers can choose according to production requirements and equipment performance.

Centrifugal Extractor

CWL-M centrifugal extractor is a new, efficient and energy-saving liquid-liquid extraction and separation equipment. It is an improvement and innovation on the traditional extraction machine and can meet the extraction, back extraction, washing and other operations in various fields.

CWL-M centrifugal extractor is an independent product developed and produced by Zhengzhou Tiei Extraction after years of hard work. It is mainly developed to address the shortcomings of traditional centrifugal extractors. This equipment is very energy-saving, with power consumption of only 10% to 30% of traditional annular gap models. At the same time, the centrifugal extractor has good extraction effect, high extraction efficiency, and saves investment costs and solvent recovery and regeneration costs.

- Working principle: Under the action of centrifugal force, the heavy phase moves away from the center of the drum and flows toward the drum wall and upward, while the light phase moves in the opposite direction. Two inlets and two outlets: the heavy phase outlet is at the top and the light phase outlet is at the bottom; the material can be customized and selected according to the liquid system, and there are corrosion-resistant materials.

- Performance advantages: small footprint, space saving; high single-stage efficiency, high extraction rate; low power consumption, good energy-saving effect; fully automatic operation, no need for human monitoring.

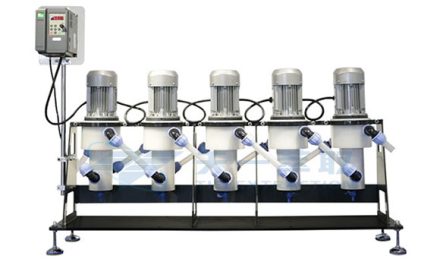

Mixer Settler

Mixer settler is a mature extraction equipment that has been used in industry for a long time and is still widely used. It is a step-by-step contact extraction equipment that achieves two-phase separation by gravity. It mainly consists of two parts: the mixing chamber and the settling chamber.

- Principle: Gravity is used to separate the two phases. It is divided into a mixing chamber and a settling chamber in a ratio of 1:3; the material liquid enters the settling chamber through the overflow baffle through the mixing mass transfer of the mixer in the mixing chamber, and the outlet is opened according to the density of the two phases.

- Material design: Generally, it is selected according to the capacity, material and density of the two phases. The common types are 300ML, 1L, and 2L. The materials are: PMMA (acrylic)/PP (polypropylene); 9L material is: PMMA.

- Performance advantages: stable performance; more flexibility between levels, and lower processing and manufacturing costs.

Compared with the mixer settler, the performance advantages of the centrifugal extractor are as follows:

- The extraction efficiency is higher, and if you want to achieve the same result, the number of stages required by the centrifugal extractor is less than that of the mixer settler.

- Cost savings are mainly reflected in two aspects: lower power consumption and more savings on extractants.

- The centrifugal extractor occupies a small area, and the mixer settler requires a special site when designing. The larger the extraction volume and the more stages, the larger the site required.

The comparison between centrifugal extractor and mixer settler is as follows. Customers still need to consider many aspects when choosing the extraction equipment. Welcome contact us for more details.

Email: sales@tieiextraction.com

Whatsapp: +86 19069612820